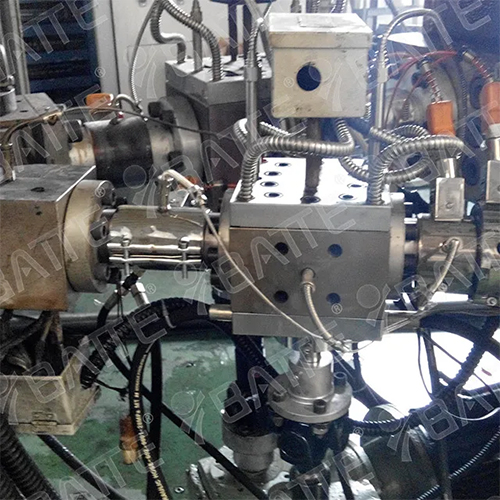

In the plastics and rubber industry, the pelletizing line is a key link, which involves the processing, mixing, melting, pelletizing and cooling of raw materials. As an important part of the pelletizing production line, the role of the melt pump cannot be ignored. This article will discuss in detail the role of melt pump in the granulation production line.

First of all, the main role of the melt pump is to ensure that the plastic and rubber raw materials in the process can be uniformly mixed and transported. In the granulation process, raw materials need to be melted at high temperatures and evenly mixed to ensure the quality and performance of the end product. Melt pumps ensure the quality and stability of the product by uniformly conveying the raw materials in the molten state into the granulator through powerful thrust and stable conveying capacity.

Secondly, melt pump helps to improve production efficiency and reduce energy consumption. In the pelletizing production line, the conveying and mixing of raw materials is a high energy consumption process. Melt pumps with efficient design and materials can reduce energy consumption and improve conveying efficiency. At the same time, the stable conveying capacity of melt pumps allows the line to maintain efficient operation, reducing downtime and maintenance, further improving production efficiency.

In addition, the melt pump also has the role of temperature control and pressure regulation. During the granulation process, temperature and pressure control are critical to product quality and stability. Melt pumps are able to accurately control the temperature and pressure of the raw material to ensure stability and uniformity in the conveying and mixing process. This accurate temperature and pressure control helps to reduce fluctuations and abnormalities in the production process, improving product qualification and stability.

In summary, the melt pump plays a vital role in the pelletizing production line. It not only ensures uniform mixing and conveying of raw materials, improves production efficiency and reduces energy consumption, but also has accurate temperature and pressure control. Therefore, choosing the right melt pump is of great significance to improve the efficiency and product quality of granulation production line.

In practice, the choice of melt pump should be based on the specific needs of the production line. Factors to be considered include melt pump conveying capacity, temperature control range, pressure regulation accuracy and material compatibility. At the same time, in order to ensure the normal operation and service life of the melt pump, it is also necessary to carry out regular maintenance and repair.

Regular maintenance helps to identify and solve potential problems in a timely manner, avoiding equipment failures and production interruptions. Maintenance includes checking whether the seals, bearings and other wear parts of the melt pump are intact, cleaning up residues and dirt, as well as replacing wear parts regularly. In addition, the temperature, pressure and other parameters of the melt pump should also be checked regularly to ensure its normal operation and effectiveness of use.

In addition to choosing the right melt pump and maintenance, operator training and management is also crucial. Operators need to have certain professional knowledge and skills to be able to properly operate and maintain the melt pump. At the same time, it should also establish sound operating procedures and management system to regulate the behavior of operators to ensure production safety and product quality.

In short, the melt pump in the granulation production line has a pivotal role. In order to improve production efficiency and product quality, we should choose the right melt pump and its regular maintenance and repair. At the same time, strengthening the operator's training and management is also essential. Only in this way can we give full play to the role of the melt pump and promote the efficient and stable operation of the granulation line.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071