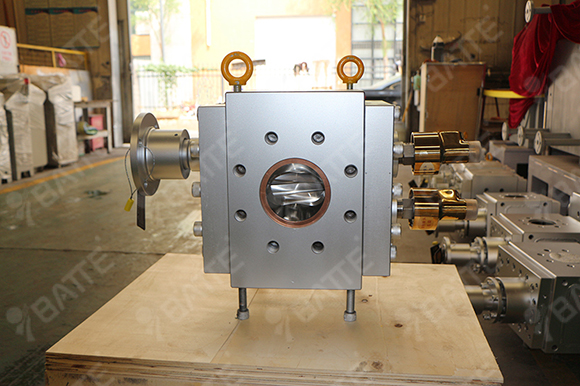

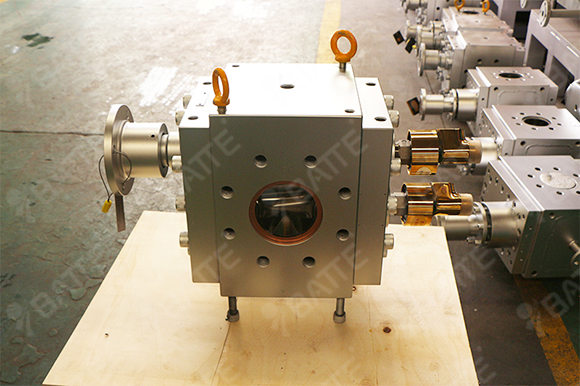

melt pump for rubber sheet

ZB-R extrusion rubber pump Introduction:

ZB-R series extrusion rubber pump is efficiently self-cleaning. The structure for shaft sleeves is simple, while the fluid passageway is specially designed. All of this make the pulsation rate become much lower under the higher differential pressure. This series of rubber gear pumps for extruder applies to butadiene rubber, chloroprene rubber, EPDM, SBR, NBR, natural rubber, etc.

melt pump in rubber extruder

Technical Parameter of ZB-R rubber gear pumps for extruder:

◆ Material for Melt Pump Body: High temperature tool steel or chromenickle steel

◆ Material for Gear: High temperature tool steel or nitrided steel

◆ Material for Sliding Bearing: High temperature tool steel, special materials or coating

◆ Shaft Sealing: Spiral Discharging

◆ Heating System: Heating medium heating

◆ Cooling System: Shaft end cooling

◆ Model/Volume Range: 50CC - 2500CC, 50cm3/rev - 2500cm3/rev

Operating Parameter of ZB-R extrusion rubber pump:

◆ Mooney ML1+4(100): to 120

◆ Working Temperature: ≤130℃

◆ Cleaning Temperature:≤350℃

◆ Inlet Pressure: ≤70MPa

◆ Differential Pressure: ≤50MPa

First-generation and second-generation rubber pumps:

Batte has rich experience in manufacturing melt gear pumps for rubber, and adopts good materials and advanced technology to provide good products for customers and meet different requirements.

rubber melting machine pump for sheet extruder

ZB-R extrusion rubber pump.pdf

ZB-R extrusion rubber pump.pdf

Batte chinaplas:

Batte melt pump factory:

batte’s domestic professional melt pump manufacturer provides special melt pump equipment of different specifications and models: ZB-C reinforced melt pump, ZB-R rubber pump, ZB-H high temperature and high pressure melt pump, etc. To learn more about relevant melt pump cases, info@battemachinery.com.