Blown film production is generally divided into single machine and multi-layer co-extrusion production methods, and by product is also divided into different products such as agricultural film (greenhouse film), packaging film, bag making film and other production.

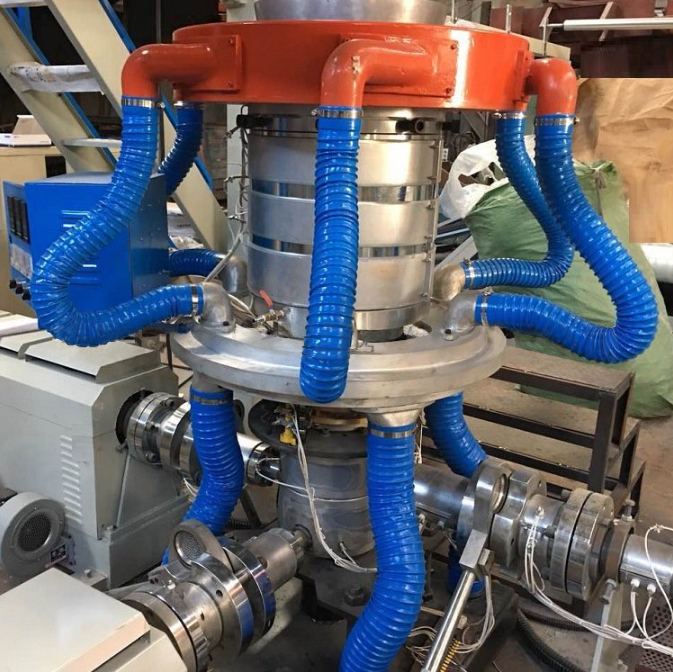

Multi-layer co-extrusion blown film installation solutions

Multi-layer co-extrusion film blowing refers to the production method of co-extrusion of multiple extruders with more than 2 layers, which is also divided into two ways: up-blowing and down-blowing, down-blowing is common for packaging film and up-blowing is the main method for agricultural film. Many film blowing machines come with cartridge type and manual screen changer. When installing screen changer, remove the original screen changer and choose Ruxing plate type duplex screen changer, which has a pressure of 50MPA, no stopping to change the screen, no leakage, and is widely recognized by customers.

Single machine blown film installation plan

Single machine blown film can be installed with single plate duplex screen changer without stopping to change the screen, but when changing the screen, it may break the film, especially for film production, so it may be necessary to re-draw the film, so single machine production usually adopts the way of stopping to change the screen.

Small-scale blown film installation solution

Small blown film production is generally based on the production of packaging film and tote bag film, single machine production, generally using cartridge type screen changer, manual screen changer is more common, can choose plate type screen changer and mesh belt type automatic screen changer, plate type screen changer is also stopping to change the screen, compared to the manual screen changer only when the screen change time is shortened, the impact on production has not improved. Batte belt type automatic screen changer (35MPA pressure), no manual operation, fully automatic production, continuous production without impact, no material leakage, is a very good choice, but also the more cost-effective choice.

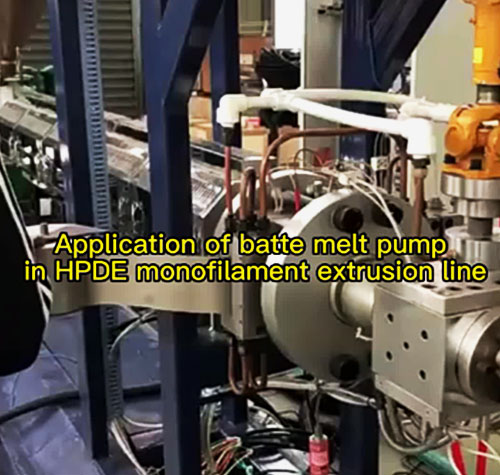

In order to the stable extrusion of products, to exclude the extrusion fluctuation caused by melt pressure, voltage, temperature, etc. ( this fluctuation, can make the geometry of extruded products with time and small changes ), now most of the foreign extrusion equipment has been equipped with melt pump. According to the different processing properties of raw mateials, melt pump gear shape can be divided into spur gear, helical gear and herringbone gear. From small extruders to extrusion capacity of 35000kg / h ultra-large extruder have the corresponding melt pump with it. As the melt pump - generally need to use the plastic melt to lubricate the pump bearing, need to ensure lubrication, but also to prevent melt leakage, technical requirements are more difficult. Most of the advanced foreign extrusion blow molding and cast production lines for high-quality film production use melt pumps to ensure the quality of their film production.

The main features of melt gear pumps

1. it can be applied to high temperature (510℃) high pressure (70MPa) high viscosity (20,000Pa-s) working conditions.

2. Optimized design of inlet and outlet, avoiding dead space in the flow channel to a large extent, reducing material residue and improving product quality.

3. improved gear parameters design, can withstand pressure and greater differential pressure.

4. Adopting special materials, high temperature resistance and long service life.

5. Adopt mechanical seal.

6. Suitable installation methods can be provided according to different site conditions of customers, more flexible and practical.

The melt pump can be installed in various ways, the input shaft of the pump can be arranged horizontally or vertically (both up and down); the driving system generally includes: motor, reducer, universal coupling, pump connector, reducer connector, etc.. The complete set of equipment includes melt pump, import/export connector, drive system, control system, etc. Customers can choose according to the specific situation. info@battemachinery.com