Plastic granulation is a critical process in the recycling and manufacturing of plastic materials. It involves converting plastic waste or raw polymer materials into uniform granules, which can then be used as feedstock for various plastic processing methods, including extrusion, injection molding, and blow molding. A melt pump plays a vital role in ensuring the efficiency and quality of the plastic granulation process within an extrusion production line.

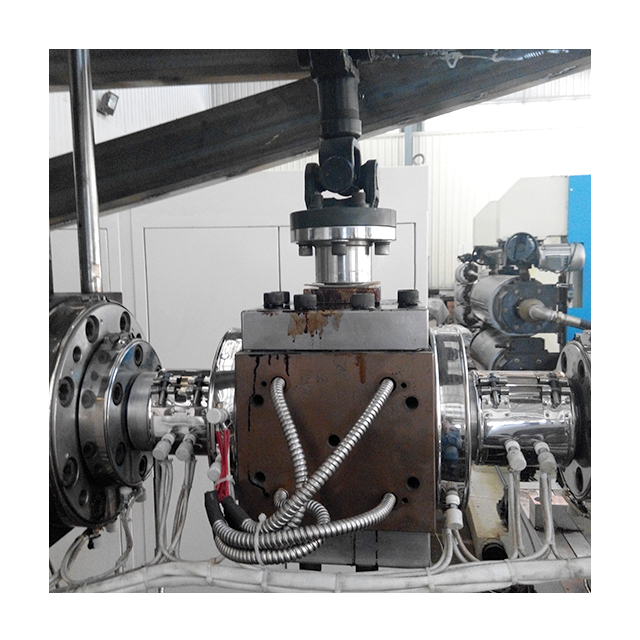

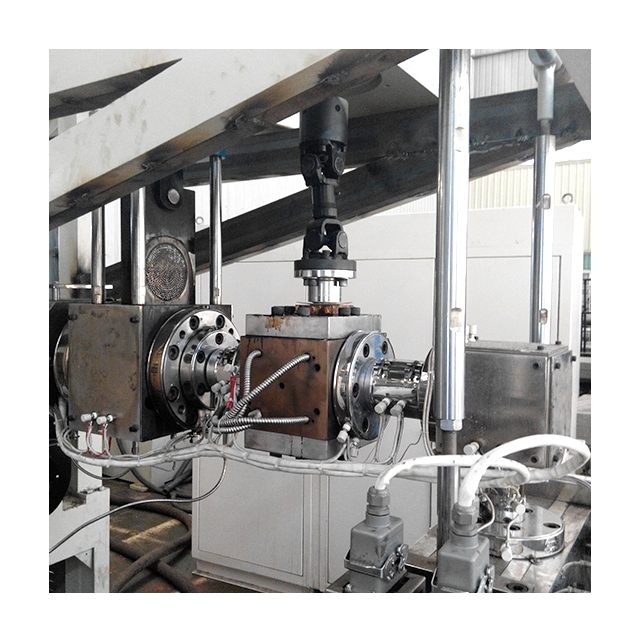

A melt pump, also known as a gear pump, is a precision device used in extrusion systems to regulate the flow of molten plastic. In plastic granulation, the melt pump is positioned between the extruder and the granulator (or pelletizer). Its primary functions include:

Pressure Stabilization: It maintains consistent pressure in the molten plastic flow, ensuring uniform granule size and shape.

Flow Control: It provides precise control over the flow rate of the molten polymer, which is critical for producing high-quality granules.

Energy Efficiency: By reducing the load on the extruder, the melt pump improves energy efficiency and reduces operational costs.

High Precision Gears: The pump is equipped with precisely engineered gears to handle the viscous nature of molten plastics, ensuring smooth and consistent flow.

Robust Construction: Made from high-strength, wear-resistant materials (e.g., tool steel or stainless steel) to withstand the abrasive nature of certain plastics and additives.

Temperature Control: Integrated heating and cooling systems to maintain optimal processing temperatures for different types of plastics.

Sealing Mechanisms: Advanced sealing systems to prevent leakage of molten plastic and ensure reliable operation.

Adaptability: Designed to handle a wide range of plastic materials, including polyethylene (PE), polypropylene (PP), polystyrene (PS), and engineering plastics.

Improved Granule Quality: Consistent pressure and flow rate result in uniform granule size, shape, and density, which are essential for downstream processing.

Enhanced Process Stability: The melt pump reduces pressure fluctuations, minimizing variations in the granulation process.

Increased Throughput: By stabilizing the flow, the melt pump allows for higher production rates without compromising quality.

Reduced Material Waste: Precise control over the extrusion process minimizes material waste, leading to cost savings and more sustainable production.

Energy Savings: The melt pump reduces the load on the extruder, lowering energy consumption and operational costs.

Recycling Lines: Used in plastic recycling systems to process post-consumer or post-industrial plastic waste into reusable granules.

Compounding Lines: Essential for producing compounded plastic materials with additives, fillers, or reinforcements.

Masterbatch Production: Ensures consistent dispersion of colorants or additives in masterbatch manufacturing.

Virgin Polymer Processing: Used in the production of granules from raw polymer materials for various industrial applications.

Extrusion: The plastic material is melted and homogenized in the extruder.

Melt Pump: The molten plastic is fed into the melt pump, which stabilizes the pressure and controls the flow rate.

Die Face Cutting or Strand Pelletizing: The molten plastic is forced through a die, and the extruded strands or sheets are cut into granules by a pelletizer.

Cooling and Collection: The granules are cooled, dried, and collected for storage or further processing.

The plastic granulation melt pump is a crucial component in extrusion-based granulation systems, offering significant advantages in terms of process stability, product quality, and energy efficiency. Its ability to handle a wide range of plastic materials and adapt to different production requirements makes it an indispensable tool in the plastic recycling and manufacturing industries. By integrating a melt pump into the granulation line, manufacturers can achieve higher productivity, reduce waste, and produce high-quality plastic granules for various applications.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071