Suitable for conveying high viscosity, non-granular impurities in the liquid. It has a high output pressure, high viscosity of the transmission medium, the use of high temperature, the input port can be vacuum, speed adjustment convenience, large flow characteristics. Pump material temperature wear-resistant, corrosion-resistant, with sufficient strength and dimensional stability.

Belonging to the positive displacement pump, work rely on the main, driven gear intermeshing caused by changes in work volume to transport the melt. Working volume by the pump body, gear tooth groove and the bearing with a side plate function. When the gear rotates, the melt enters the tooth spaces of the two gears of the suction chamber. As the melt is rotated, the melt is brought into the discharge chamber from both sides, the gears mesh again, and the melt in the tooth spaces is pushed out of the discharge chamber, Pressure to the export pipeline. Bearings can not use the usual lubricating grease to avoid contamination of the melt, usually using melt self-lubricating

(1), used in the polymerization reaction process, used to transport high viscosity melt.

(2), used in melt spinning, as a booster pump.

(3), used in the extruder or injection molding machine to improve the extrusion efficiency and reduce the load on the extruder.

(4), used to convey resin, melt resin, melt evenly, build pressure to the die.

Batte chinaplas:

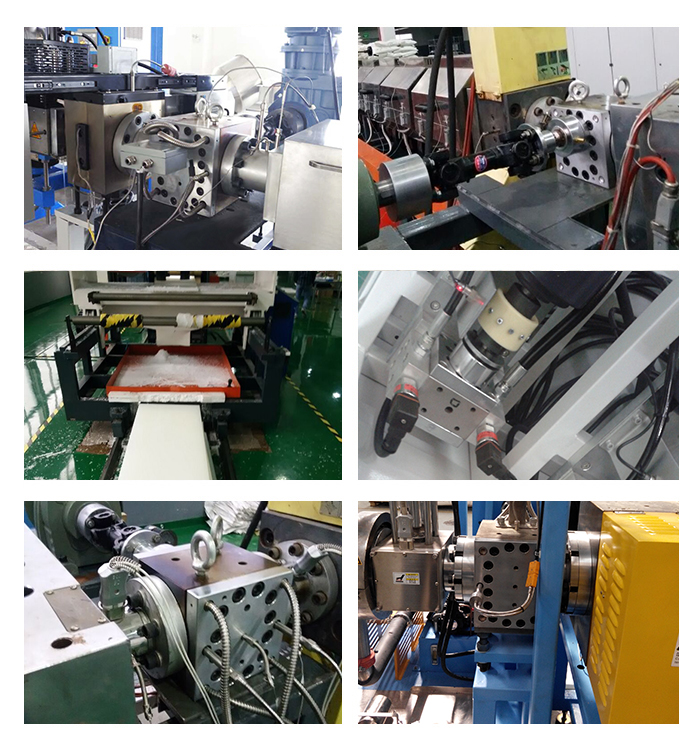

Batte melt pump factory:

batte’s domestic professional melt pump manufacturer provides special melt pump equipment of different specifications and models: ZB-C reinforced melt pump, ZB-R rubber pump, ZB-H high temperature and high pressure melt pump, etc. To learn more about relevant melt pump cases, info@battemachinery.com.