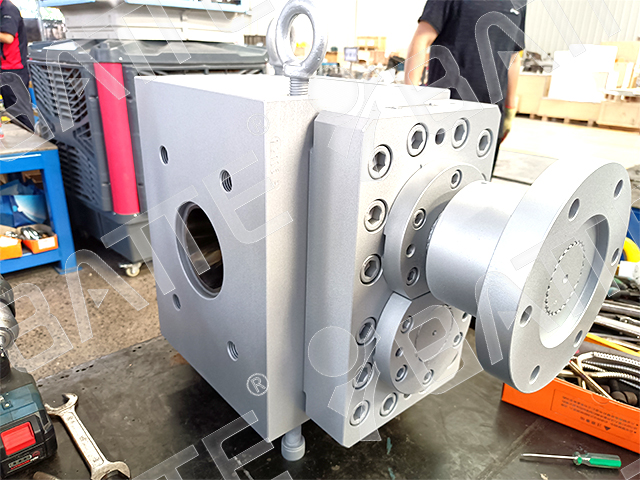

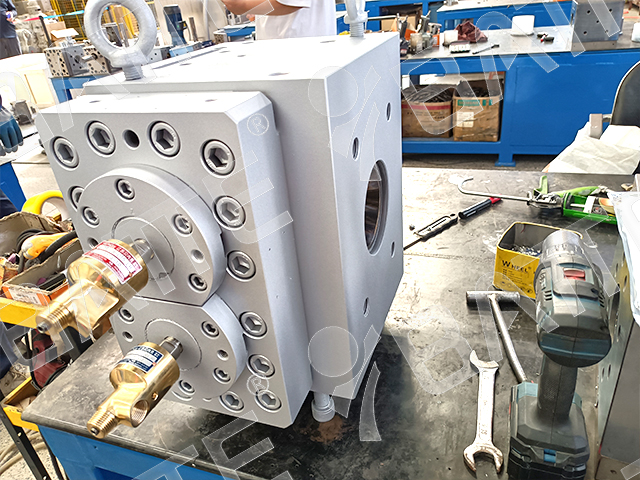

TPU melt pumps play a crucial role in extrusion systems for elastomers and biodegradable plastics. Their unique internal structure provides efficient self-cleaning functionality, typically installed between the extruder outlet and die head for pressurization, pressure stabilization, and metering. These melt pumps are widely used in processes involving polybutadiene rubber, chloroprene rubber, EPDM, SBR, EVA, natural rubber, and other materials.

Key features of TPU melt pumps include:

Suitable for high-pressure (40 MPa) and high-viscosity (40,000 Pa•s) operating conditions.

Highly polished flow channels, nearly mirror-like, particularly suitable for heat-sensitive materials.

Precision-engineered structure with high temperature control accuracy.

Optimized flow channels and lubrication system, featuring efficient self-cleaning functionality with no residual material and no dead zones.

As a professional manufacturer of melt gear pumps, BATTE Melt Pumps provides a wide range of melt gear pump specifications for the resin, synthetic fiber, rubber, and other polymer materials industries, catering to various polymer processing conditions. The company offers a comprehensive range of melt gear pump specifications, from 0.05 CC to 30,000 CC, and can also provide customized solutions tailored to specific user requirements.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071