I. Structural Features of the Underwater Cutting Start-Up Valve

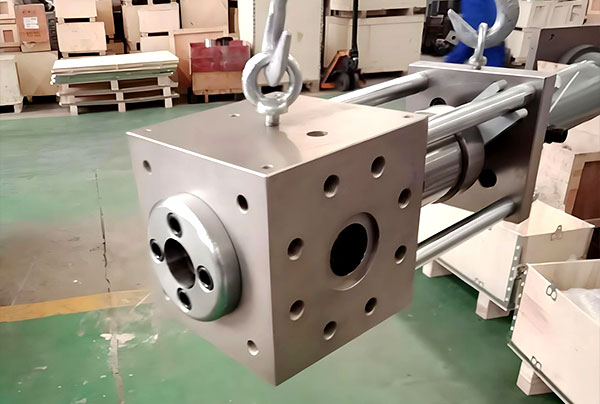

1. Dual-Position Flow Channel Design:

Working Position: Designed as a straight-through flow channel to ensure smooth material flow to downstream equipment during normal production.

Discharge Position: Features a 90° flow channel design to facilitate material discharge when required, such as during filter screen replacement or flow channel cleaning.

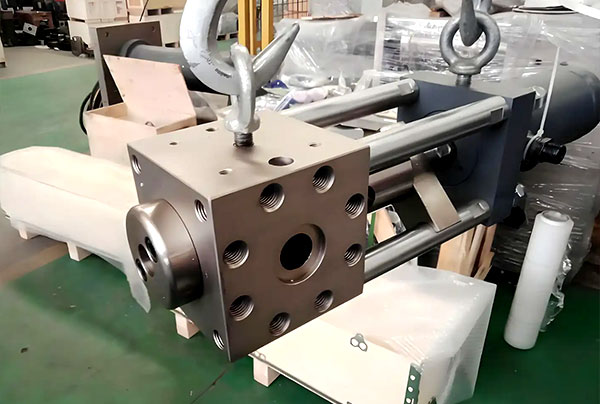

2. Main Structure:

Similar to a single-column screen changer but optimized for extruder-specific requirements.

Main body material can be selected based on material properties, including corrosion-resistant treatment and corrosion-resistant materials to accommodate corrosive materials.

II. Standard Configuration of Underwater Cutting Start-up Valve

The standard configuration of an extruder start-up valve typically includes three major components:

Start-up Valve Body: The core component carrying material flow, featuring a dual-position flow channel design.

Hydraulic Power Unit: Provides power to the start-up valve, ensuring rapid and precise valve switching.

Electrical Control Cabinet: Controls the operation of the hydraulic power unit and heating system, enabling automated control.

Customers may also select additional configurations based on actual needs, such as adding sensors or alarms, to enhance production line safety and reliability.

III. Heating Methods for Submerged Cutting Valves

To accommodate diverse materials and production environments, submerged cutting valves offer two heating options:

Electric Heating: Suitable for most materials and conditions, providing rapid heating with easy control.

Thermal Fluid Heating: Ideal for high-temperature applications or materials sensitive to electric heating, utilizing circulating thermal fluid for heating.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071