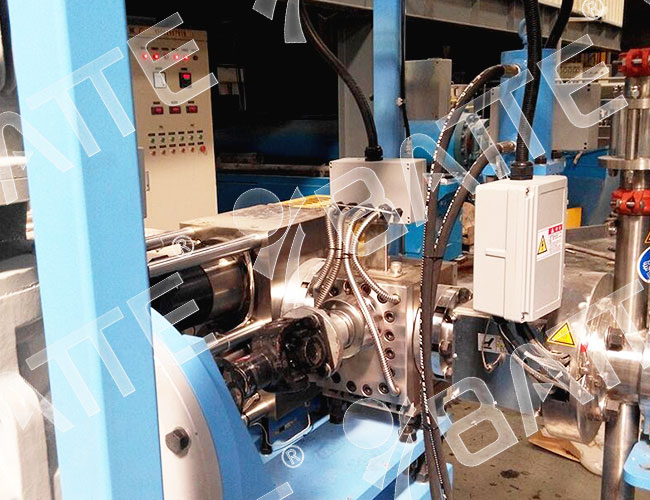

The PU granulation melt pump screen changer is an indispensable key equipment in the plastic processing process, playing an important role in ensuring production continuity and product quality. However, as the usage time increases, the screen changer may experience wear, blockage, or other malfunctions, which require timely maintenance and replacement.

When replacing the PU granulation melt pump screen changer, the first step is to ensure the safety and cleanliness of the operating environment. Staff should wear protective equipment and strictly follow operating procedures. At the same time, the necessary tools and new mesh changers should be prepared to ensure the smooth progress of the replacement process.

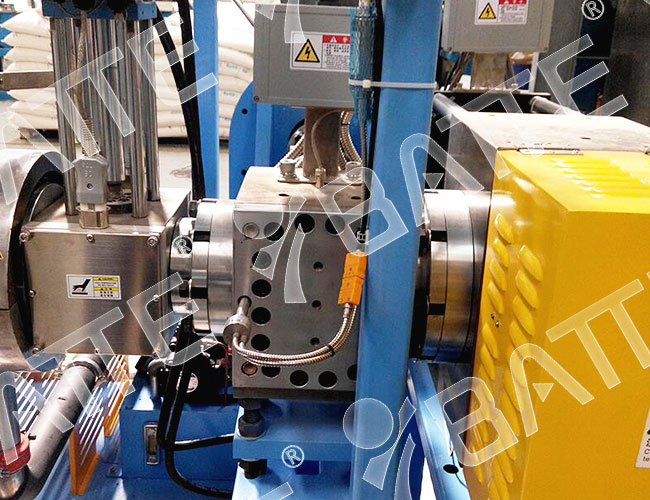

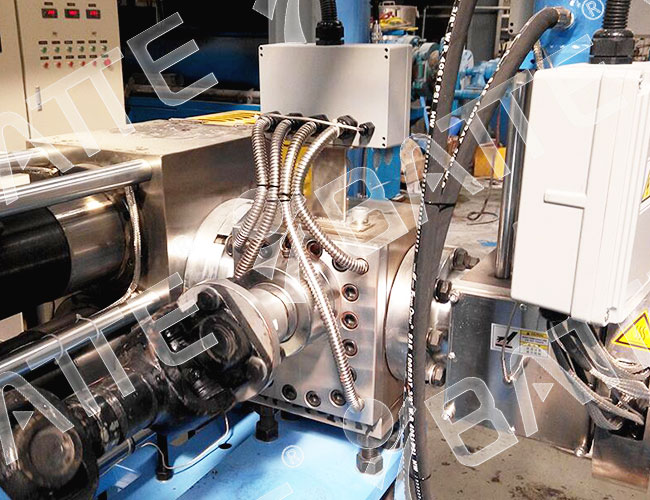

When dismantling the old screen changer, special attention should be paid not to damage the pipes and other equipment connected to it. During the disassembly process, the connecting components should be loosened one by one and the old screen changer should be carefully removed. When installing a new screen changer, ensure that the connections between the components are tight and reliable, and check for any leaks.

In addition to replacing the screen changer itself, attention should also be paid to other components related to the screen changer, such as the melt pump, filter, etc. The degree of wear of these components can also affect the stability of the entire production process and product quality. Therefore, while replacing the screen changer, consideration should also be given to inspecting and maintaining these components.

In addition, in order to extend the service life of the screen changer and improve production efficiency, the following points should also be noted: first, regularly clean the screen changer to prevent blockage and scaling; The second is to regularly check the sealing performance of the screen changer to ensure no leakage phenomenon; The third is to use and maintain the screen changer reasonably to avoid excessive wear and damage.

In summary, The replacement of the PU granulation melt pump screen changer is an important and complex task. Only by making sufficient preparations and strictly following the operating procedures can the smooth replacement process and stable production process be ensured.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071