The PET packaging tape requires uniform and consistent color, so the core component of the packaging tape, the melt pump, plays a crucial role! The thickness of the packaging tape is closely related to the precision of the melt pump. Optimizing the internal flow channel of the melt pump can avoid the reaction caused by long-term accumulation of raw materials and reduce the original material performance of the packaging tape!

Melt pumps are mainly used for the transportation, pressurization, and metering of high-temperature and high viscosity polymer melts. Widely used in extrusion molding of plastic, resin, rubber, and chemical fiber products. Industries such as granulation, film, pipe, sheet, sheet, artificial fiber, optical fiber, medical plastic catheters, etc. In the extrusion system, the melt pump mainly plays three roles: 1. Boosting and stabilizing pressure; 2. Control pressure fluctuations; 3. Reduce energy consumption and increase production.

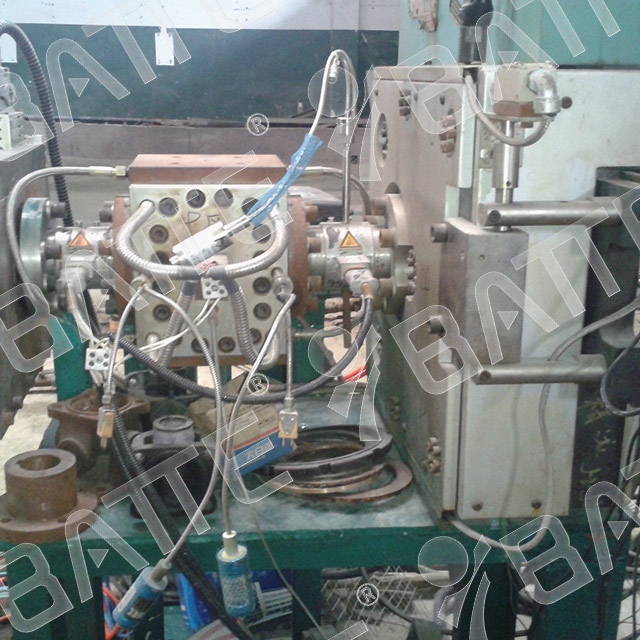

The PET packaging belt melt pump is made of specially made alloy materials that have undergone strict forging, surface heat treatment, and precision metal processing technology; We have adopted high-quality heat treatment processes and strict quality control systems to ensure the durability of our products.

Optimized structural design of PET packaging belt melt pump, completely eliminating fluctuations in melt pressure and temperature; It completely eliminates bubble and impurity defects; Completely eliminate product defects caused by resin aging and black spots; The stability of resin pressure and material flow, along with the rapid development of e-commerce and the increasing demand in the packaging industry. The company has invested a lot of effort in developing a more durable and uniform flow rate melt metering pump for packaging belts! The thickness error of the packaging tape pumped out by the melt pump is extremely small, and the original performance of the material is guaranteed!

Email: info@battemachinery.com

WhatsApp: +86 158 38331071