In the PVC granulation process, hydraulic screen changer is a key equipment, and its selection has a significant impact on production efficiency and product quality. When selecting a hydraulic screen changer, the following aspects need to be considered:

1、 Material of the screen changer

The material of hydraulic screen changer has a crucial impact on its durability and reliability. Due to the large amount of heat and friction generated during the PVC granulation process, selecting high-quality materials can ensure the service life and stability of the mesh changer. Generally speaking, commonly used materials include stainless steel, nickel based alloys, and Hastelloy alloys, which have good corrosion resistance and high temperature performance and can meet the production requirements of PVC granulation.

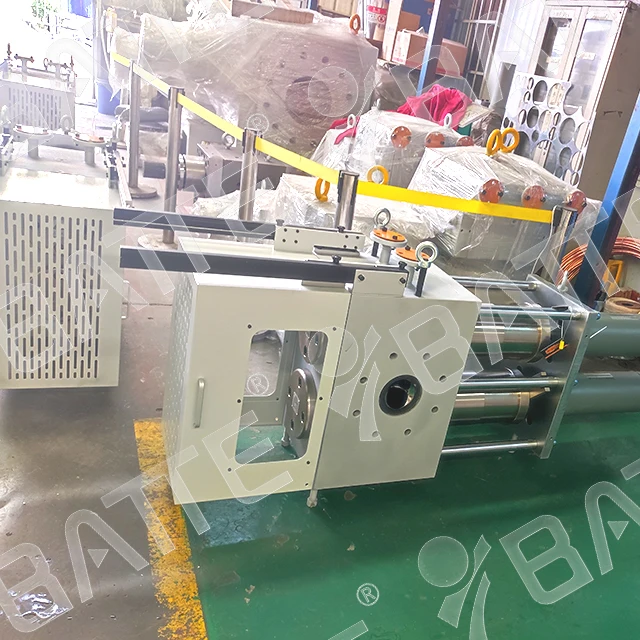

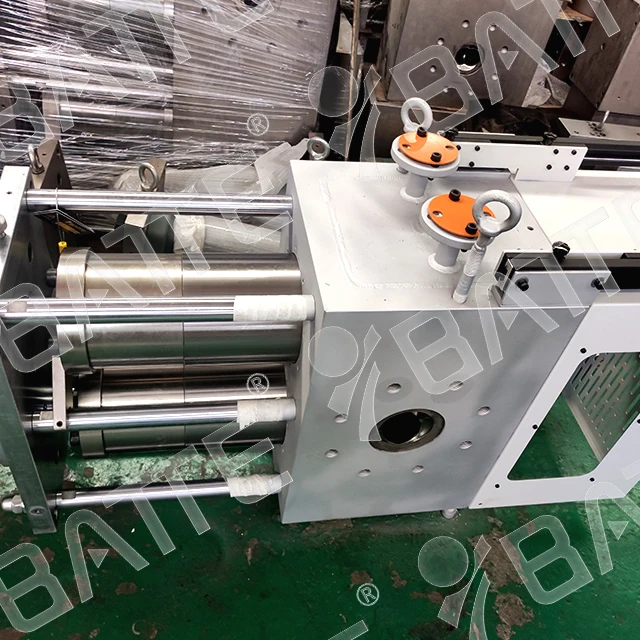

2、 The structural form of the screen changer

Hydraulic screen changers have various structural forms, commonly including manual and automatic screen changers. The manual screen changer requires manual replacement of the filter screen during production, which is more complicated to operate, but the price is relatively low. The automatic screen changer can automatically replace the filter screen when a certain pressure or flow rate is reached, which is easy to operate but expensive. According to production demand and budget situation, suitable structural forms can be selected.

3、 The filtering area of the screen changer

The larger the filtering area of the hydraulic screen changer, the higher the production efficiency. Therefore, when selecting a hydraulic screen changer, it is necessary to determine the appropriate filtration area based on the requirements of production capacity. If the filtering area is too small, it will lead to low production efficiency; If the filtering area is too large, it will increase investment and maintenance costs.

4、 The method of replacing the filter screen of the screen changer

The hydraulic screen changer requires shutdown operation when replacing the filter screen. Therefore, selecting the appropriate method of replacing the filter screen has a significant impact on production efficiency and product quality. Generally speaking, the methods for replacing filters include manual replacement, automatic replacement, and online replacement. Manual replacement requires manual operation and is slow; Automatic replacement can automatically replace the filter under certain pressure or flow conditions, with simple operation; Online replacement can replace the filter screen without stopping the machine, but corresponding auxiliary equipment needs to be configured. Choose a suitable method for replacing the filter screen based on production needs and actual situation.

5、 Supporting equipment for screen changer

The hydraulic screen changer needs to be used in conjunction with corresponding supporting equipment, such as hydraulic pumps, pipelines, valves, etc. The performance and quality of these devices have a significant impact on the stability and reliability of the entire production system. Therefore, when selecting a hydraulic screen changer, it is necessary to consider the performance and quality requirements of its supporting equipment to ensure the stability and reliability of the entire production system.

In summary, selecting a suitable hydraulic screen changer requires consideration of multiple aspects, including material, structural form, filtration area, filter replacement method, and supporting equipment. It is necessary to comprehensively consider production needs and actual situations to ensure the improvement of production efficiency and product quality.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071