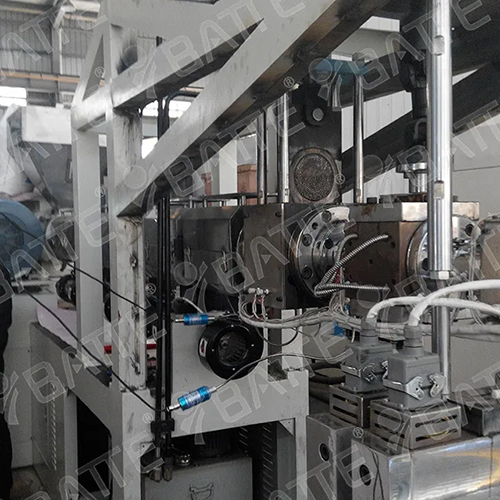

Melt pumps are mainly used for high temperature and high viscosity polymer melt conveying, pressurizing and metering. It is characterized by compact structure, reliable operation, low energy consumption, high volumetric efficiency and small shearing effect on the melt. Melt pumps are usually used together with extruders in plastics processing, which can make the melt further homogenization, stable flow at high temperature and high pressure, no pulsation of material output, high volumetric efficiency, small shear effect on the melt, thus improving the quality of the products and the precision of the products, and reducing the cost. It can be applied to plastic melt pelletizing and mixing, as well as extruding sheets, pipes, films and profiles.

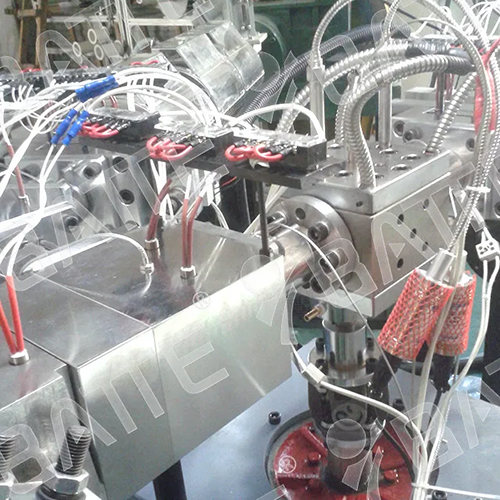

A complete melt pump includes melt pump, motor, reducer, coupling, control and safety devices composed of several parts, the melt pump is mainly composed of pump casing, active gear, driven gear, sliding bearings, front and rear end plates, packing seals and so on. The melt pump utilizes self-lubrication of melt, and the sliding bearing is opened with lubrication groove holes, which works under high temperature and high pressure and has good wear resistance. It can work continuously at 350℃ and pressure 35Mp or higher.

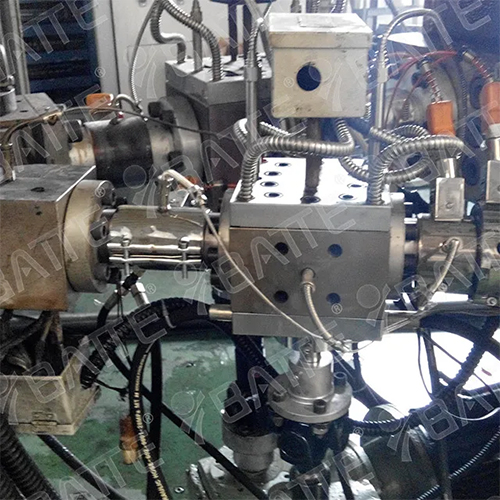

Melt pump is a positive displacement conveying device, the flow rate is strictly proportional to the pump speed. It mainly consists of pump casing, main gear, driven gear, sliding bearing, front and rear end plates, packing seal and so on. The tooth profile of the two gears, the pump body, the side cover plate constitutes the feeding area, transmission area and discharge area of the pump. When working, it relies on the working volume change caused by the mutual meshing of the master and slave gears to convey the melt.

The working volume consists of the pump body, the gear's tooth groove and the bearing with the function of side plate (i.e. feeding area). When the gear rotates in the specified direction, the melt enters into the grooves of the two gears in the feed area, and as the gears rotate, the melt is brought into the delivery area from both sides, and the gears mesh again, so that the melt in the grooves is extruded out of the discharge area, and pressurized to the outlet pipe. As long as the pump shaft rotates, the gears will press the melt to the outlet side, so the pump outlet can reach a very high pressure, while the inlet flow and pressure is not too high requirements. Melt pumps are involute external gear pumps (most commonly used in plastic melt transfer), which can be categorized into straight, helical, herringbone, etc. according to the tooth direction.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071