Application and characteristics of melt metering pump

Suitable for conveying liquids with high viscosity and no particulate impurities. It has the characteristics of high output pressure, high viscosity of the conveying medium, high operating temperature, vacuum input, convenient speed adjustment, and a large flow range. The material of the pump is temperature resistant, wear-resistant, corrosion-resistant, and has sufficient strength and dimensional stability.

Application scope of melt metering pump

(1) Used in the polymerization reaction process to transport high viscosity melt.

(2) Used in melt spinning as a booster pump.

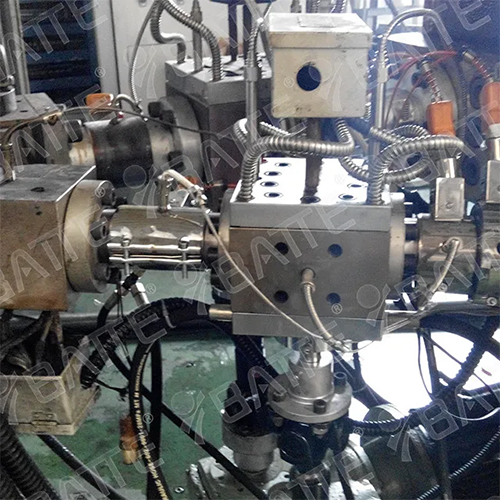

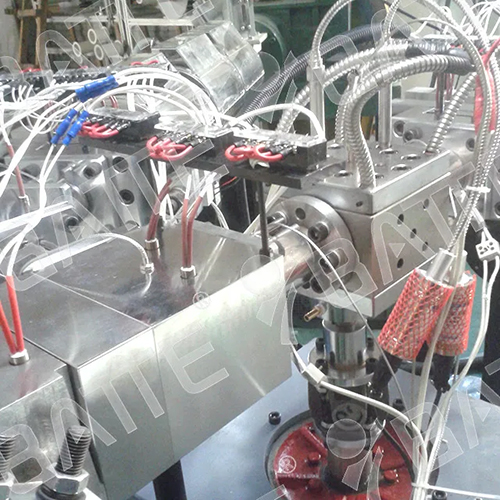

(3) Applied to extruders or injection molding machines to improve extrusion efficiency and reduce extruder load.

(4) Used for conveying resin and molten resin, making the melt uniform and applying pressure to the mold head.

Working principle of melt metering pump

Belonging to a positive displacement pump, it relies on the meshing of the main and driven gears to cause changes in the working volume during operation to transport molten material. The working volume is composed of the pump body, the gear teeth, and a bearing sleeve with side plate function. When the gear rotates, the melt enters the grooves of the two gears in the suction chamber. As it rotates, the melt is brought into the discharge chamber from both sides, and the gears mesh again, causing the melt in the grooves to be squeezed out of the discharge chamber and sent to the outlet pipeline. Bearings cannot use the usual lubricating grease to avoid contaminating the melt, and melt self-lubricating is usually used.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071