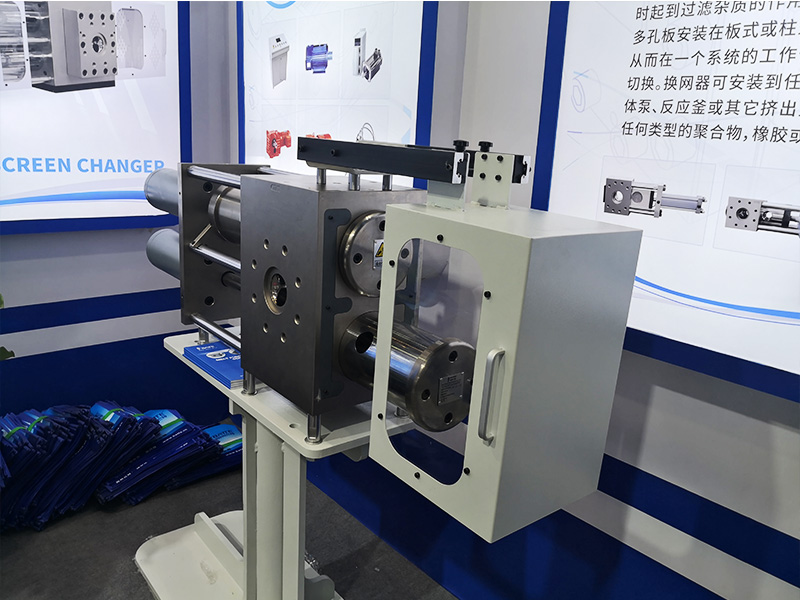

Zhengzhou Batte is one of the earliest domestic production enterprises to conduct research and development of non-stop hydraulic screen changers, with more than 20 years of rich successful experience in continuous exploration and innovation in the field of screen changers. The screen changer products provided by Zhengzhou Batte all have optimized flow channel designs, which can fully achieve non-stop and material leakage during the extruder screen changing process, and completely avoid product defects caused by bubbles during the screen changing process. The company compares high-quality and low-quality screen changers from the following five aspects.

1. Design

The appearance of the screen changer looks similar, but the internal design is different. The big difference lies in the different sealing methods. At present, the reliable sealing method is to use a gap fit hard sealing method. At that time, the technical content of this was to have gaps for pushing and pulling activities to replace the mesh, while also ensuring no material leakage. There were not many mesh changer manufacturers in the market that achieved this. Another sealing method is through soft sealing, which uses materials with different hardness for sealing. When this type of mesh changer is pushed and pulled under high pressure, it causes wear on the softer sealing material, increases the gap, and inevitably leads to material leakage. Some may leak when installed, while others may leak after brief production. Therefore, the difference between good and bad can be distinguished in design.

2. Material wise

The key components of high-quality mesh exchangers are made of special alloy steel materials. After corresponding heat treatment, the surface hardness reaches a reasonable height, and the precision of the clearance is ensured through friction in the hard seal. The hardness of ordinary steel cannot be achieved, and pushing and pulling will cause tensile damage and material leakage. At the same time, the material used for connecting the main body of the screen changer will also differ in terms of forged parts, steel parts, and cast parts, which will naturally reflect differences in price and quality.

3. Processing technology

In order to ensure the surface hardness of key components of the screen changer, corresponding treatment processes need to be carried out. Simply processing them into machined parts with the same appearance cannot guarantee the quality of the screen changer. Even with relevant treatment processes, differences in process methods and time can also lead to differences in the quality of the screen changer, which is also where the quality of the screen changer varies in the market.

4. Assembly

Professional screen changer manufacturers have accumulated and accumulated rich experience in assembly. It is precisely because of the differences between professionals and non professionals, and the different mastery of core technologies, that the essential difference in screen changer is that it does not leak materials.

5. Price

I believe the first question everyone asks when consulting about a extruder screen changer is: How much does it cost to replace the screen changer? The cost of mechanical processing is transparent and can be accounted for. When you blindly pursue low prices, how can you ensure the quality of the screen changer? It is not necessary to engage in commercial activities. A low-priced screen changer is definitely not a high-quality one, and of course, a high priced screen changer is not necessarily a high-quality one. It can be certain that a high-quality screen changer is not a very cheap one.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071