Melt metering pumps can be widely used in the extrusion molding of meltblown cloth, nonwoven fabrics, plastics, resins, and rubber products, such as meltblown cloth machine, pelletizing, films, tubes, plates and sheets, bi-directional stretch films, fiber optic cables, plastics processing, adhesive production, and precision extrusion, and other industries.

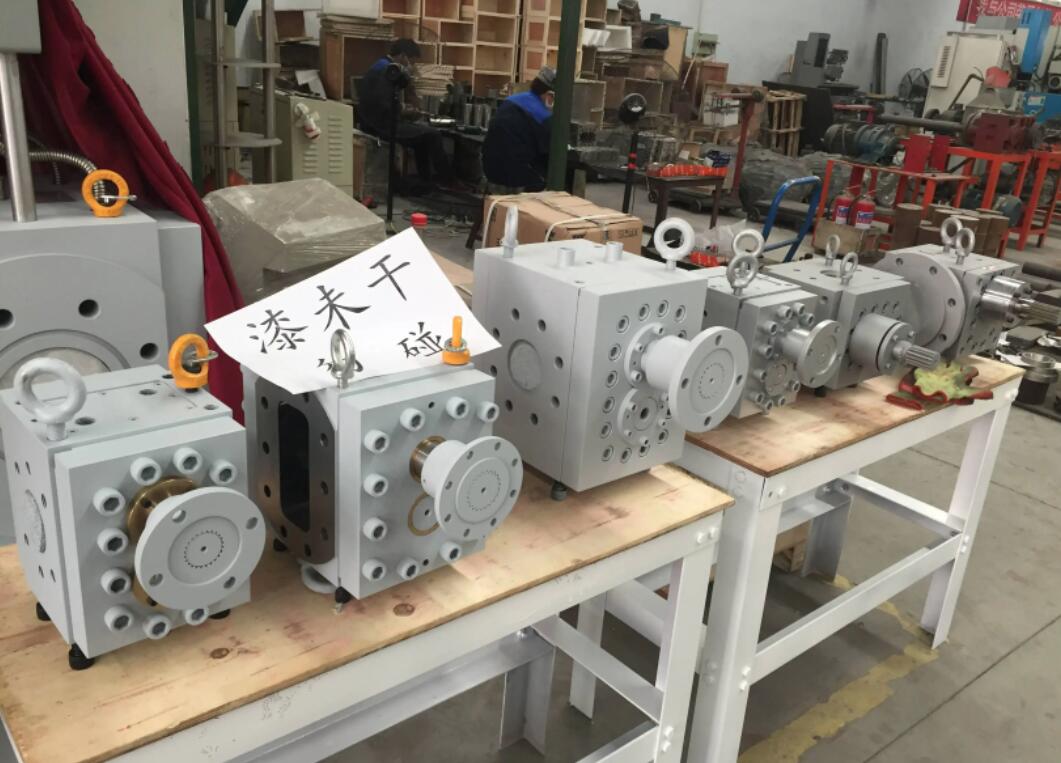

The melt metering pumps made by our company adopt inclined shaft design, involute bevel gear technology and European standard material fittings, etc., which have the advantages of stabilizing the output pressure, improving the product quality, enhancing the stability of the whole machine, prolonging the life of the extruder, lowering the energy consumption per unit, saving the consumption of raw materials, and applying to many fields. The models of melt metering pumps range from 0.5CC-12000CC, and can also be customized according to user requirements.

Features of melt metering pump:

1、Sealing generally adopts spiral seal, with good anti-wear performance.

2、Driving motor+gear reducer+universal coupling+pump body, the motor adopts frequency conversion speed control or servo speed control, which can be adjusted to the required flow at will. For the product to see, high precision requirements, it is recommended to use servo motor speed control.

3、Melt metering pump is heated by electric heating rod, which can accurately control the melt temperature. Melt metering pump belongs to volumetric gear pump, using an external meshing cylindrical gear (helical teeth) relative rotation to transport and deliver high viscosity fluid. All gears and mating surfaces are finely ground, and assembly clearance is strictly controlled to obtain accurate flow.

4、The pump body is set with unloading orifice to strictly control the output pressure fluctuation of the system.

5、The system is equipped with end bearing flushing orifices, which can ensure the bearings work for a long time.

6、The pump body cavity adopts high temperature liquid hydrodynamic design to ensure large working conditions for feeding as well as discharging bins, and to improve the product meshing performance.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071