Melt gear pumps, as the core equipment in the polymer production process, can transport a wide range of materials, can be used for different pressure conditions, a variety of low-temperature, low-viscosity polymers to high-temperature, high-viscosity polymer reaction transport. For the melt gear pump application scenarios and conveying materials to analyze the introduction?

First,can be used in the extrusion system, pressure stabilization, improve product quality

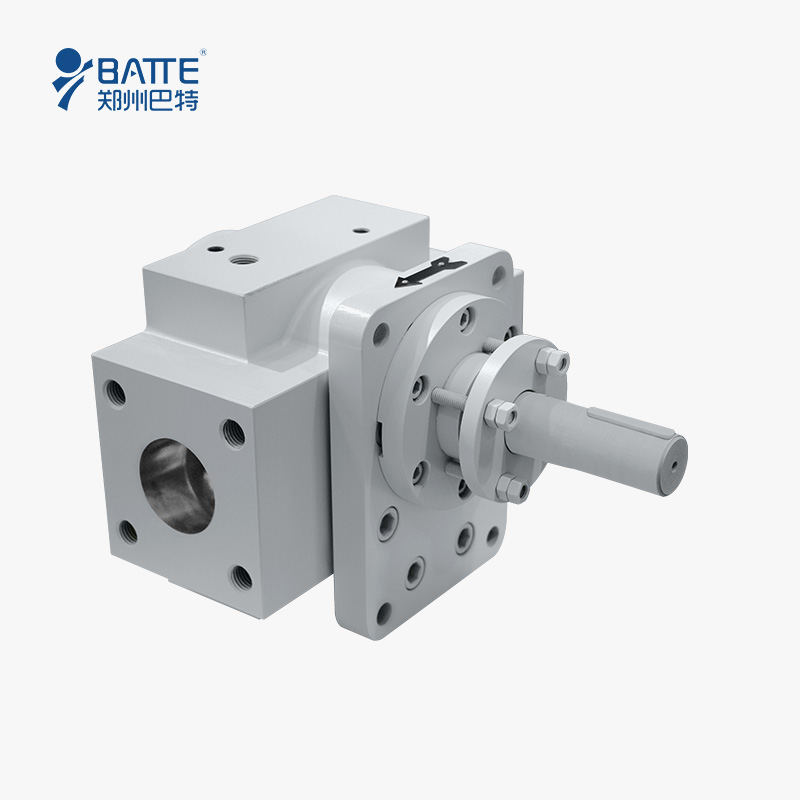

Melt gear pumps can be used in extrusion molding of plastics, resins, rubber products, such as granulation, film, pipe, plate, sheet and other industries, installed between the extruder outlet and die head, to boost, stabilize pressure, metering role. Gear pumps used in the extrusion system, the technical difficulty lies in the high requirement of wear resistance, generally using electric heating.

Second, can be used in a variety of resins, chemical fibers, rubber and other industries polymer production process

In the polymer reaction process, melt gear pumps can convey materials such as: PP, PET, PE, PC, PA6, EVA, PLA, PC, TPU and so on. Other polymer materials industry in the original liquid, solution, glue, oligomer, prepolymer, etc.; as well as hot melt adhesives, asphalt, paints, adhesives, pharmaceuticals, food, grease, fuel, oil, dyes, paints, lubricants, polyols and other materials that do not contain particulate impurities.

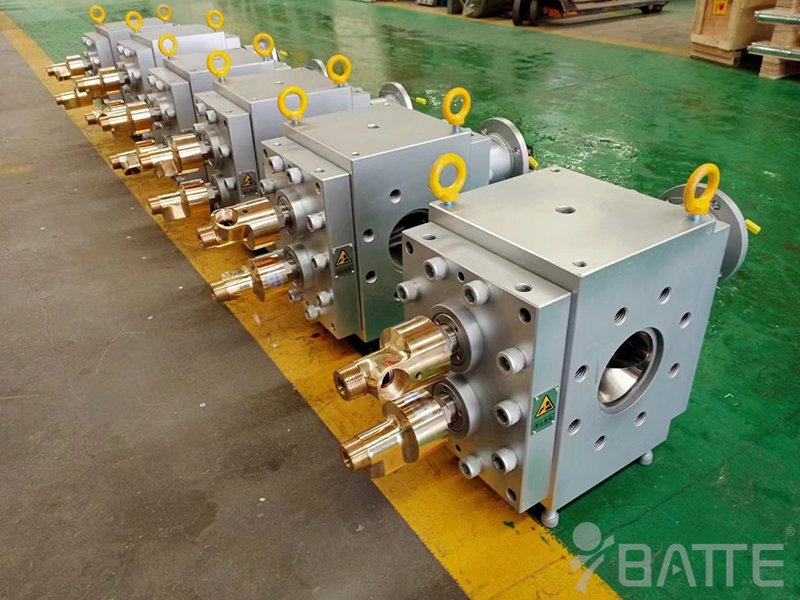

In the large polymer reaction process, the required gear pump specifications are generally larger, and the whole production line has higher requirements for the precision, reliability and service life of the gear pumps, and the production process of this type of pumps is complicated and technologically advanced. Manufacturers provide large specification melt gear pump models up to 12000CC, can meet the production needs of most working conditions.

Third,can be used in a variety of petroleum, chemical, pharmaceutical, food and other industrial processes

Melt gear pumps can be used in a variety of petroleum, chemical, pharmaceutical, food and other industrial processes, used to transport a certain viscosity, relatively pure materials without particulate impurities. In the chemical production process, the requirements for melt gear pumps are: high production precision, good wear resistance, corrosion resistance. Due to a variety of complex working conditions on the different requirements of wear and corrosion resistance, this type of pump generally need to be customized production.

BATTE is a professional manufacturer of melt gear pumps, over the years is committed to providing users with good quality gear pump products, currently has a full range of products covering all working conditions, full specification gear pumps, can provide professional and customized solutions for different customer requirements.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071