Melt pumps can work continuously at high temperatures up to 350C and pressures up to 35MP or higher. Its main function is to pressurize and stabilize the high temperature plastic melt from the extruder, and keep the melt flow accurately and stably into the extruder head. When the melt at the inlet of the pump produces large pressure fluctuations due to various reasons, the pressure fluctuations caused at the outlet are extremely small. Its ability to stabilize melt pressure and flow is superior to various types of extruders. Its main features are simple and compact structure, reliable operation and long life.

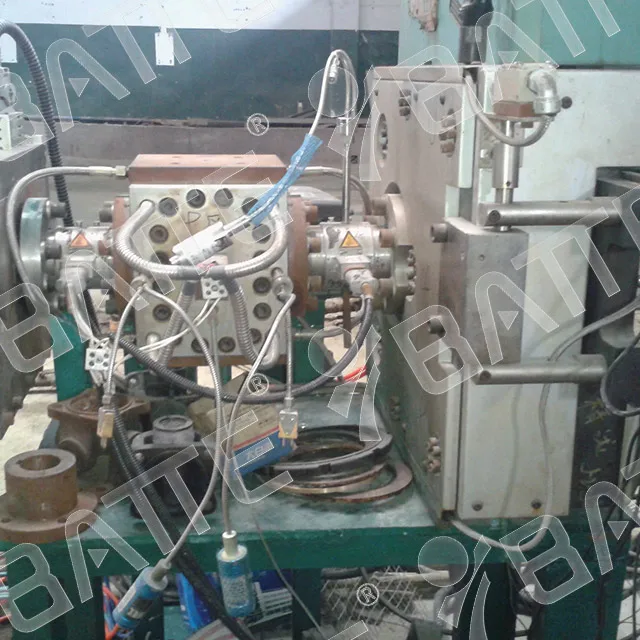

thermoplastic melt pump

As the melt pump is in the high temperature, high pressure conditions of continuous work, and transportation of plastic melt generally has a high viscosity, and some also has a certain degree of corrosiveness. Therefore, the melt pump material requirements are very high, need to have temperature resistance, wear resistance, corrosion resistance, and to have sufficient strength and dimensional stability. Usually, melt pumps are mainly made of alloy tool steel, gears and shafts are made into a single unit, so that they work more reliably under high torque conditions.

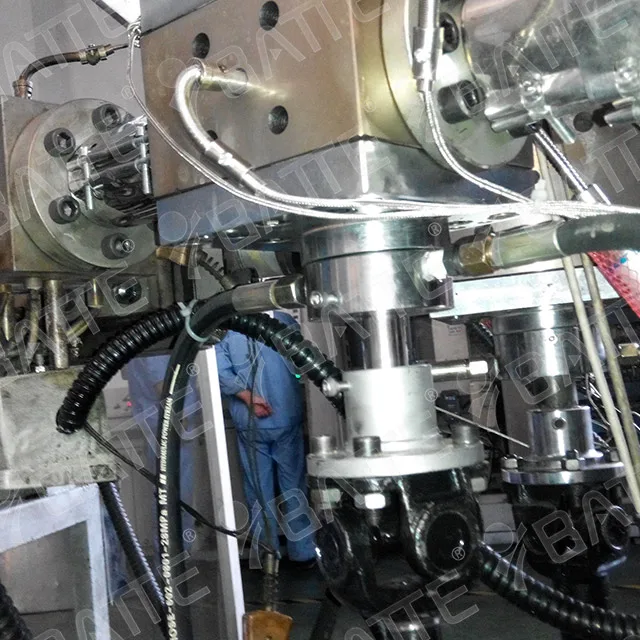

polymer melt pump

Melt pump lubrication and sealing issues are more complex, in order to prevent contamination of the plastic melt, it can not use the general lubricant or grease lubrication, but with the help of transporting the plastic melt for self-lubrication. Therefore, the melt pump bearing and sealing structure must be adapted to the special properties of the plastic melt. For small and medium-sized melt pumps are generally heated and insulated with electric heat, while large melt pumps use jacketed pump body with fluid temperature control.

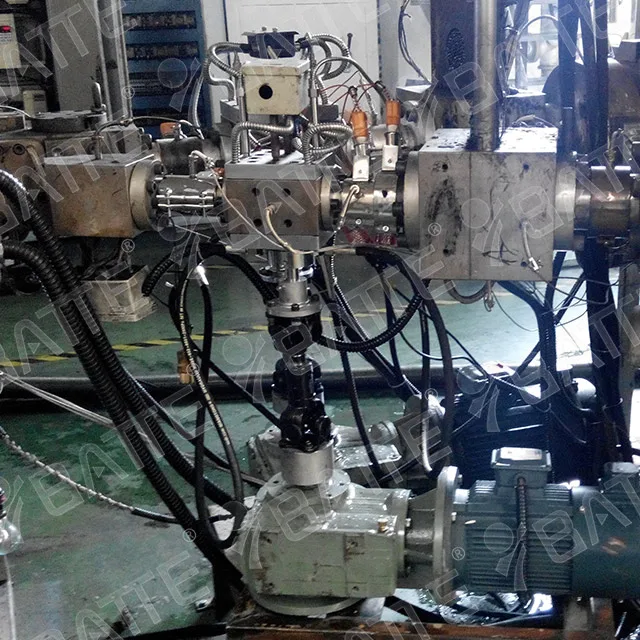

melt pump in extruder

The composition of the melt pump mainly includes the pump body, front and rear side panels, two intermeshing gears, bearings and seals. Through the tooth profile of the two gears, the pump body and the side plate formed by the space, the formation of the pump into the section area, conveying area and discharge area. Gear is the core part of the melt pump, its structure in various forms, according to the meshing method can be divided into internal and external meshing mode; according to the tooth profile curve can be divided into involute gears, arc gears, cycloid gears, etc.; according to the tooth direction can be divided into straight gears, helical gears and herringbone gears. However, in the process of conveying plastic melt, the most commonly used is involute straight teeth or helical teeth of the external gear pump.

plastic extruder melt pump

BATTE melt pumps are very familiar with the extrusion process of all kinds of plastic and rubber materials, and have a lot of experience in the application of melt pumps for extrusion systems, and are able to provide a wide range of melt pumps for various extrusion systems for sheet, plate, pipe, film, wire drawing, underwater pelletizing, masterbatch extrusion pelletizing, and rubber preforms.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071