Melt gear pump is a common industrial equipment, mainly used for transferring high temperature melt. It plays an important role in many industries, such as plastic processing, chemical, rubber, grease and so on. This article will introduce the role of melt gear pumps from different angles. Melt gear pumps enable efficient melt transfer. In the plastics processing industry, melt gear pumps are widely used in injection molding machines, extruders and other equipment. It conveys the melt from the low-pressure area to the high-pressure area through the rotation of the gears, so that the plastic raw material can be injected or extruded smoothly. Melt gear pumps have the advantages of strong conveying capacity and stable flow rate, which can ensure the stability of the plastic processing process and improve the production efficiency.

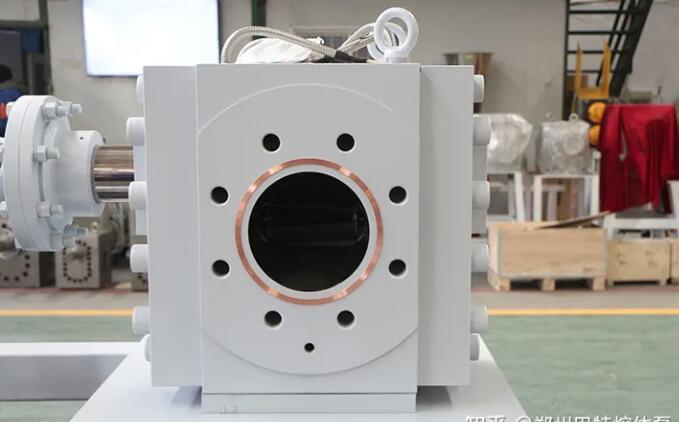

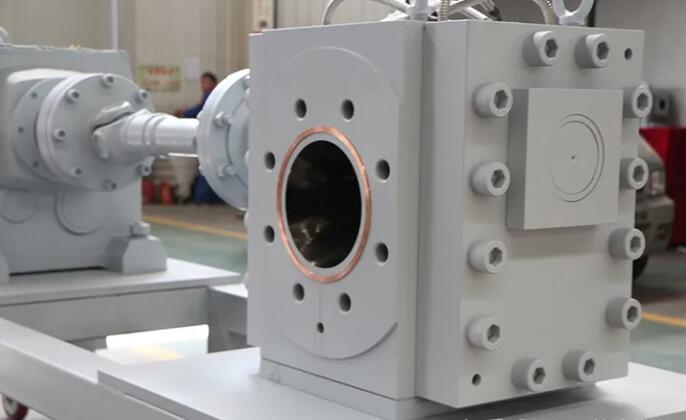

melt pump for extruder

Melt gear pump can ensure the temperature control of the melt, in the process of high temperature melt conveying, melt gear pump can effectively prevent the melt from overheating or overcooling through reasonable design and high quality material selection. It has good thermal conductivity and high temperature resistance, and can work stably in a high temperature environment to ensure that the temperature of the melt is within the appropriate range. Polymer melt pumps are also able to provide stable pressure. In the chemical industry, many chemical processes need to be carried out under certain pressure conditions, such as polymerization and reaction. By controlling the speed and transmission ratio of the gears, the plastic extruder melt pump is able to provide the required pressure to ensure that the chemical process is carried out properly. It is characterized by stable pressure and wide adjustment range, which can meet different process requirements.

plastic extruder melt pump

Melt pumps for extruder can also provide good sealing performance. Leakage is a common problem during the transportation of high-temperature melts, which can lead to energy waste and environmental pollution. Melt gear pumps adopt special sealing structure and materials, which can effectively prevent leakage and ensure the safety of melt transportation and environmental protection. Melt gear pumps can also provide good wear resistance. In the high temperature and high pressure working environment melt gear pumps need to withstand greater friction and impact. It adopts high-strength materials and advanced manufacturing process, which can work stably for a long time under harsh working conditions, with long service life and low maintenance cost.

melt pump design

Melt pump has an important role in plastic processing, chemical, rubber, grease and other industries. It can realize efficient melt conveying, ensure temperature control of the melt, provide stable pressure, provide good sealing performance, as well as provide good wear resistance. The wide application of melt gear pumps not only improves production efficiency and reduces energy consumption, but also promotes the development and progress of industry.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071