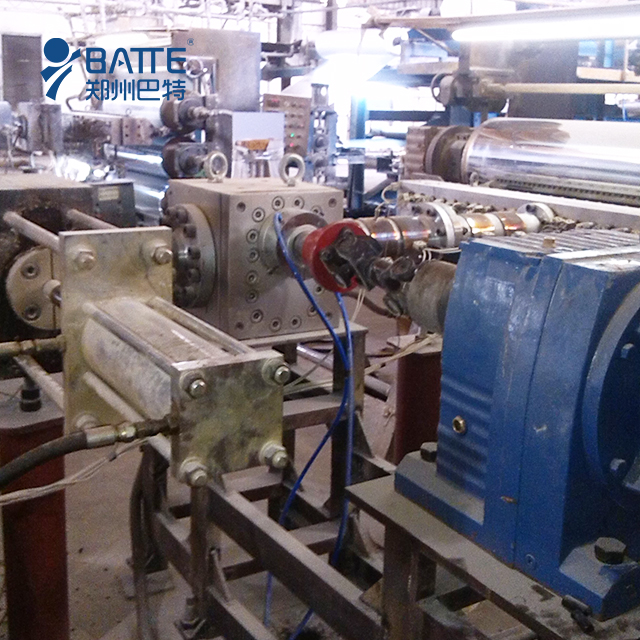

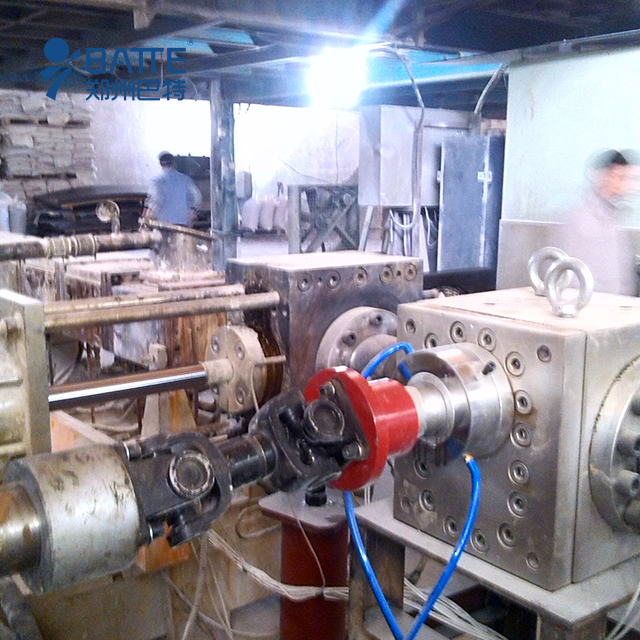

The BATTE aluminum plastic plate extrusion melt gear pump is a melt pump used for conveying plastic melts. Its main function is to pressurize and stabilize the high-temperature plastic melt from the plasticizing and mixing equipment, and maintain a stable flow rate of the melt into the extrusion mold. It can operate at high temperatures up to 350 ° C and pressures up to 35 MPa or higher. Its main characteristics are simple and compact structure, and reliable operation. The use of melt pump extrusion technology has become the mainstream in the plastic extrusion processing industry.

The application of melt pumps in the plastic extrusion processing industry has involved fields such as granulation, extrusion plate (sheet, film), extrusion pipe, blowing film, extrusion coating, profile extrusion, continuous blowing molding, etc. The processed materials almost involve all thermoplastic resins, thermoplastic elastomers, and other polymers.

The melt pump is a positive displacement conveying device, and the flow rate is strictly proportional to the pump speed. Mainly composed of pump casing, driving gear, driven gear, sliding bearings, front and rear end plates, packing seals, etc. The feeding area, conveying area, and discharge area of the pump are composed of the tooth profile of two gears, the pump body, and the side cover plate. During operation, the melt is transported by the change in working volume caused by the mutual meshing of the main and driven gears.

Usually, a melt pump can assist in the task of generating pressure. This allows the extruder to "concentrate" on feeding, melting, and mixing. When there is no melt pump, a large amount of pressure will be generated at the head of the extruder. After installing the melt pump, the highest point of pressure is located behind the pump rather than before it, which causes a decrease in pressure inside the extruder. Due to the fact that the extruder does not need to generate high pressure. Therefore, the shear strength of the corresponding melt decreases, the temperature curve is flat, and the temperature rise decreases. Considering the torque of the extruder, this will reduce energy consumption.

BATTE aluminum plastic plate extrusion melt gear pump