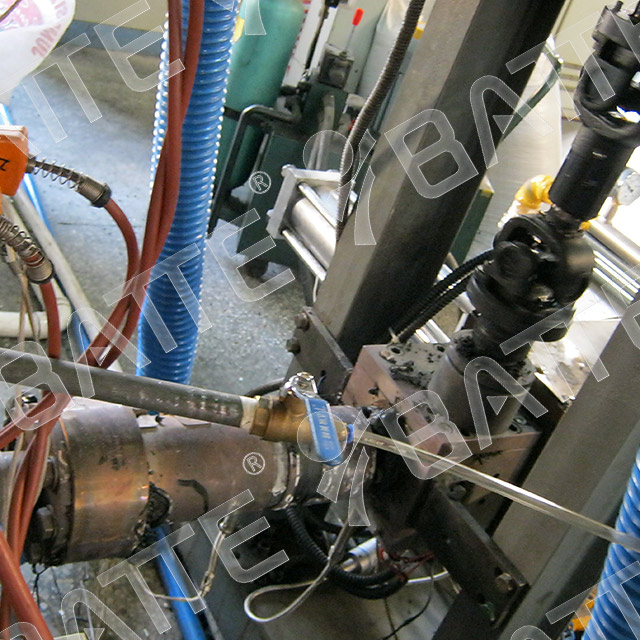

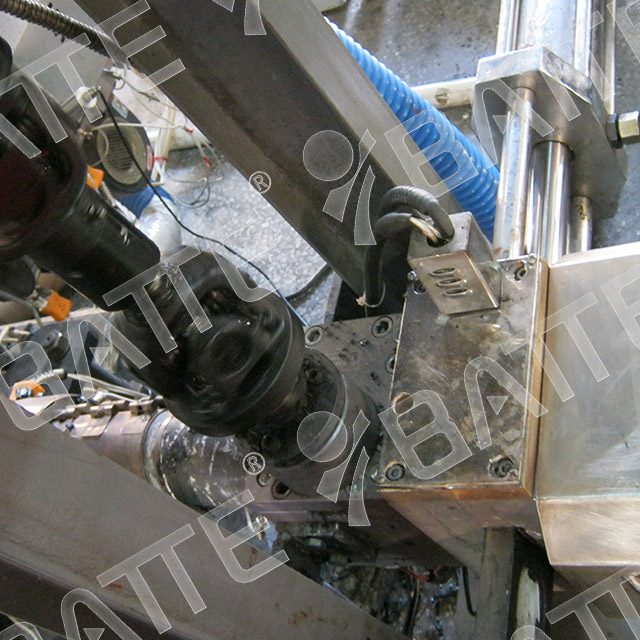

The high-pressure blown film melt pump is suitable for engineering plastics, blown film and other processes, and is suitable for high-pressure working conditions such as HDPE and PEEK.

1. Optimized melt flow channel design: eliminates dead corners within the channel, reduces polymer residue to a lower level, and improves product quality;

2. Improved gear parameter design: more precise displacement design, making the output pressure more stable and suitable for precision extrusion conditions;

3. Very wide range of applicable viscosity: using different sealing methods, it can be applied to working conditions from low viscosity to extremely high viscosity;

4. Multiple installation methods: meet the personalized needs of users;

5. High precision manufacturing and heat treatment: more precise and durable.

The pump body of the melt pump for high-temperature and high-pressure film blowing is made of CPM Tool steel and titanium tantalum alloy. The gear material of the high-temperature melt pump is: Hastelloy alloy, special material, and wear-resistant coating. The material of the sliding bearing for the high-temperature melt pump is titanium tantalum alloy. The high-temperature melt pump can operate at temperatures up to 510 ℃ and its output pressure can reach 70MPa.

Zhengzhou BATTE Melt Pump is a professional manufacturer of melt gear pumps, providing various specifications of melt gear pumps for polymer material industries such as resin, chemical fiber, rubber, etc., and providing various series of melt gear pump products that can meet all polymer working conditions. The company provides a complete range of melt gear pumps, ranging from 0.08CC to 20000CC, and can also be customized non-standard according to user needs.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071