The melt pump of the woven bag production line is mainly used for the transportation, pressurization, and metering of high-temperature and high viscosity polymer melts. The melt pump pressurizes and stabilizes the high-temperature plastic melt from the extruder, and then sends it to the extruder head with a stable flow rate. Its ability to stabilize melt pressure and flow rate is superior to various types of extruders. The application of melt pumps in extrusion systems mainly plays three roles:

When the melt pump is working, when the material at the outlet of the melt pump is subjected to resistance generated by the forming mold, the gears in the melt pump act like pistons in a cylinder barrel, exerting compression on the melt in the discharge area, achieving the pressurization function of the melt pump. This can solve the problem that the pressure built by the extruder during the production process cannot meet the actual pressure requirements of the production process. At the same time, the gears in the pump act as a rotating barrier, effectively blocking the pressure fluctuations and flow fluctuations in the feeding area from affecting the discharge area, thereby stabilizing the pressure fluctuations.

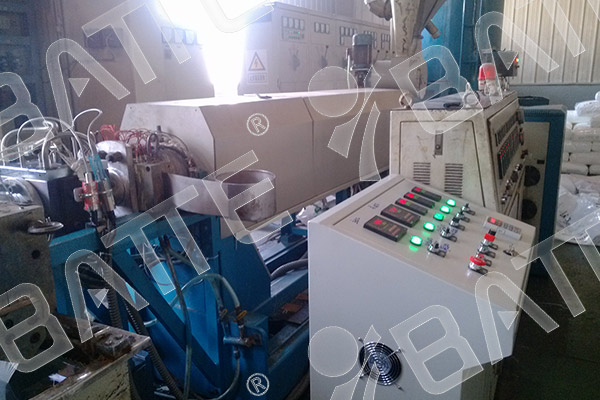

Due to the internal screw motion mechanism of the extruder, the pressure of the melt at the head of the extruder usually exhibits pulse like fluctuations. This fluctuation usually cannot be eliminated through its own PID adjustment, if a Zhengzhou Bart melt gear pump is installed at the rear of the machine head. Then, continuous meshing between teeth can be used to continuously and smoothly squeeze the material to eliminate pressure fluctuations.

For subsequent processes, ensuring smooth material flow and reducing fluctuations in melt pressure is crucial as this ensures a more stable product size. The smaller the fluctuation of melt pressure, the more uniform the thickness of pipes and sheets, which makes the size of fiber optic cables more accurately controlled.

Usually, melt gear pumps can assist in the task of generating pressure. This allows the extruder to "concentrate" on feeding, melting, and mixing. When there is no melt gear pump, a large amount of pressure will be generated at the head of the extruder. After installing the melt gear pump. The highest point of pressure is located behind the pump rather than before it, which causes a decrease in pressure inside the extruder. Due to the fact that the extruder does not need to generate high pressure. Therefore, the Shear strength of the corresponding melt decreases, the temperature curve is gentle, and the temperature rise decreases. Considering the torque of the extruder, this will reduce energy consumption.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071