The hot melt adhesive pump is mainly used for the transportation, pressurization, and metering of high-temperature and high viscosity polymer melts. Its main function is to pressurize and stabilize high-temperature melt, and maintain accurate and stable melt flow into various pipelines. Hot melt adhesive delivery pumps are used in production lines such as chemical fibers, granulation, plastic films, sheets, plates, profiles, pipes, wires and cables, wire drawing, composite extrusion, etc. The materials that can be processed almost cover most polymer materials, such as PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymers, polysulfone, polyester, thermoplastic elastomers, rubber, and thermal adhesives. It is widely used in the hot melt adhesive industry and dispensing equipment.

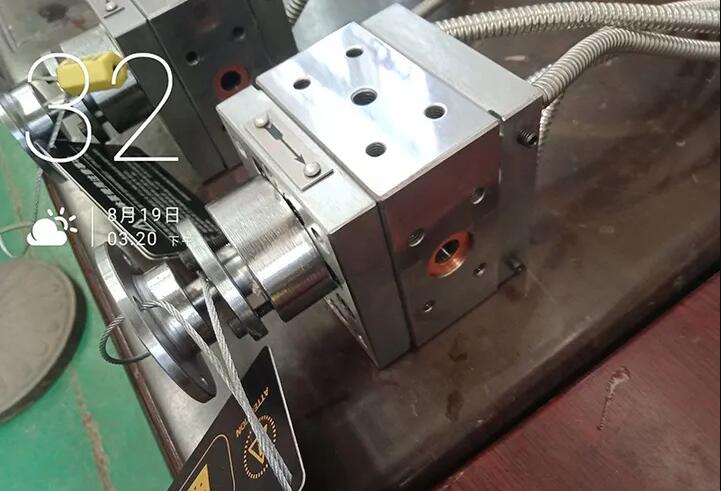

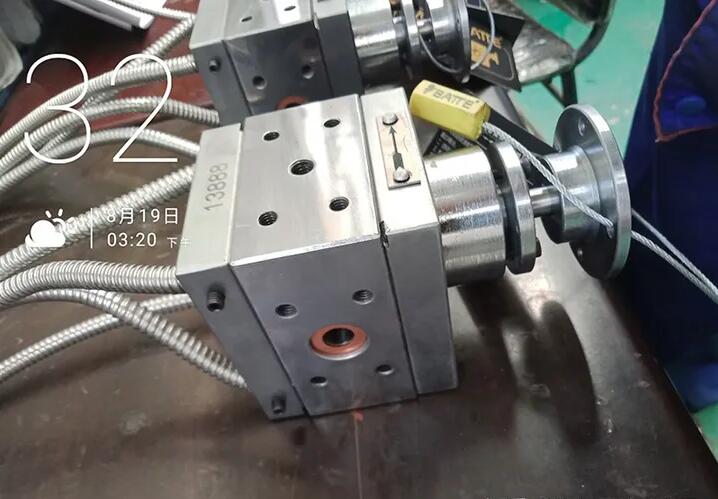

The hot melt adhesive gear pump belongs to a positive displacement pump, which relies on the meshing of the main and driven gears to cause changes in the working volume during operation to transport the melt. The working volume is composed of the pump body, the gear teeth, and a bearing sleeve with side plate function. When the gear rotates, the melt enters the grooves of the two gears in the suction chamber. As it rotates, the melt is brought into the discharge chamber from both sides, and the gears mesh again, causing the melt in the grooves to be squeezed out of the discharge chamber and sent to the outlet pipeline. Bearings cannot use the usual lubricating grease to avoid contamination of the melt, and usually use melt self-lubrication.

1. It can be applied to high temperature (350 ℃), high pressure (35MPa), high viscosity (20000Pa • s) working conditions.

2. Optimized channel design to avoid dead corners within the channel, reduce material residue, and improve product quality.

3. Improved gear parameter design ensures more stable output pressure and lower pulsation rate, making it suitable for precision extrusion.

4. Adopting high-temperature alloy steel, it has good wear resistance and long service life.

5. Adopting different sealing methods, suitable for a wide range of viscosity.

6. Suitable installation methods can be provided according to different on-site situations of customers, making them more flexible and practical.

Pump body: high-temperature tool steel, chromium nickel alloy steel

Gears: High temperature tool steel, nitrided steel, with straight or helical tooth shapes

Sliding bearing: high-temperature tool steel

Shaft seal: spiral mechanical seal, packing seal, spiral packing seal, triple seal

Heating method: electric heating

Specification/flow range: 0.5CC-12000CC

Transmission medium viscosity: 1~20000Pa • s (1000~20000000cP)

Inlet pressure: 0-30MPa

Outlet pressure: 0-40MPa

Large pressure difference: 25MPa

Operating temperature: ≤ 350 ℃

The hot melt adhesive pump can be installed in various ways, and the input shaft of the pump can be arranged horizontally or vertically (both up and down); The drive system generally includes: motor, reducer, universal coupling, pump connection head, reducer connection head, etc. The complete equipment includes a melt pump, inlet and outlet connectors, drive systems, control systems, etc. Customers can choose according to specific circumstances.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071