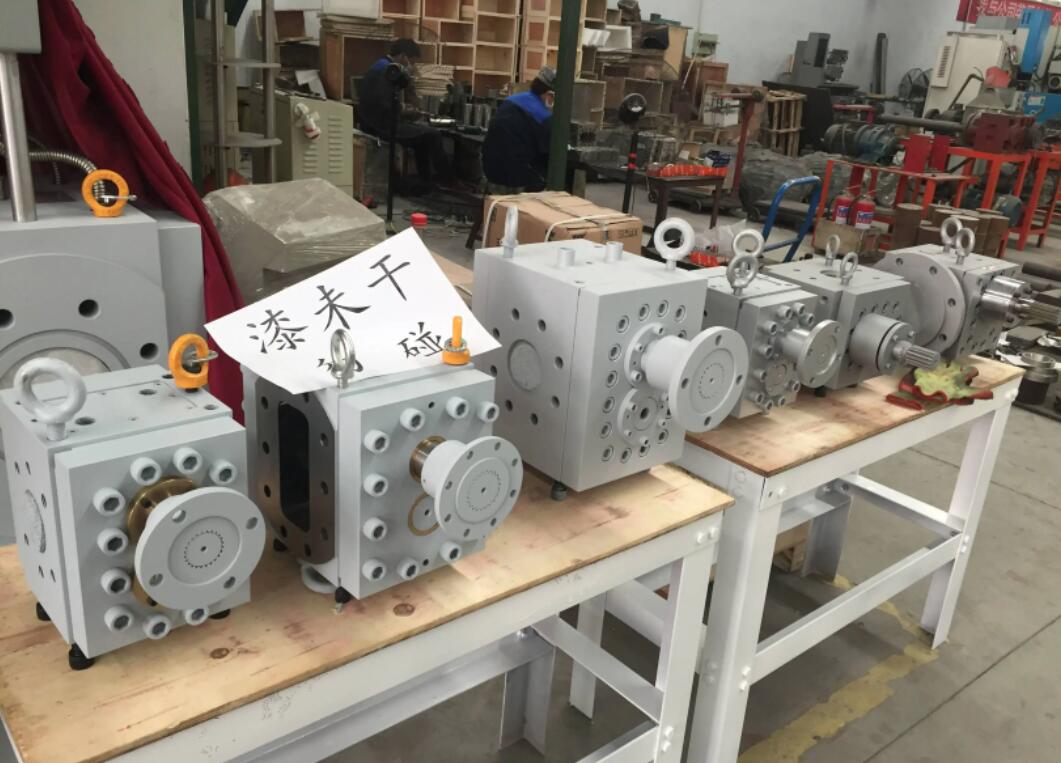

Structure of hot melt adhesive metering gear pump

The structure of the hot melt adhesive metering gear pump consists of pump casing, driving and driven gears, sliding bearings, front and rear end plates, packing seals, and other components; Rotor type: helical or straight cylindrical gear, heating method: electric heating, sealing structure: high-temperature resistant packing seal.

Working principle of hot melt adhesive metering gear pump

The hot melt adhesive metering gear pump belongs to a positive displacement pump, which relies on the meshing of the main and driven gears to change the working volume during operation to transport the melt. The working volume is composed of the pump body, the gear teeth, and a bearing sleeve with side plate function. When the gear rotates, the melt enters the grooves of the two gears in the suction chamber. As it rotates, the melt is brought into the discharge chamber from both sides, and the gears mesh again, causing the melt in the grooves to be squeezed out of the discharge chamber and sent to the outlet pipeline. Bearings cannot use the usual lubricating grease to avoid contamination of the melt, and usually use melt self-lubrication.

Installation method of hot melt adhesive metering gear pump

The hot melt adhesive metering gear pump is generally driven by a motor+reducer+universal coupling, or by a motor+reducer+elastic coupling. The hot melt adhesive metering gear pump belongs to a positive displacement forced delivery pump, and the pump output flow can be adjusted by adjusting the pump speed. It is recommended to use a frequency conversion speed regulation method to achieve near linear flow output of the gear pump. Zhengzhou Batte is melt pump for plastics manufacturing provides hot melt adhesive metering gear pumps with specifications ranging from 0.08CC-800CC, and can also be customized for non-standard production.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071