Melt metering is realized by high-precision melt metering pump. The function of the melt metering pump is to ensure that the melt provided to the die head has sufficient and stable pressure to overcome the resistance when the melt passes through the filter and achieve the uniformity of the film thickness. The melt metering pump usually adopts the oblique two gear pump. In order to further improve the metering accuracy, some choose the three gear pump. Because the pulse of the three gear pump is smaller than that of the two gear pump, the fluctuation of the pump output is also small. The heating temperature of the melt metering pump is 270 ℃ - 280 ℃.

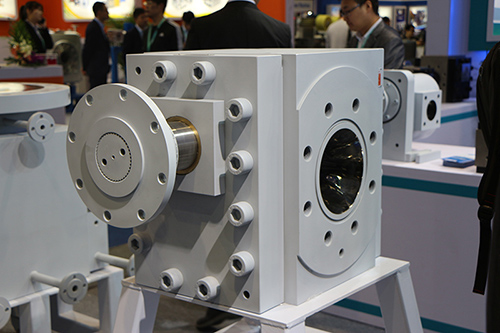

In order to remove impurities, gel particles and other foreign matters that may exist in the melt, a screen changer is often installed on the BOPET plastic film production line. The screen changer for BOPET film adopts a dual channel and dual filter screen structure. When the screen is changed, one screen will work and one screen will be replaced without interrupting the material flow and product, so as to realize the screen change without stopping the machine. Zhengzhou Bart Factory can specially design and process various sizes and specifications according to user needs.

Zhengzhou Batte, a domestic professional melt pump and screen changer manufacturer, provides melt conveying, metering, pressurization and filtration solutions for thousands of domestic enterprise users. Whether BOPP, BOPET, BOPP, BOPE, we can provide customers with technical solutions for polymer melt pump and hydraulic screen changer that match the process requirements. Welcome to consult us. info@battemachinery.com