Rubber extrusion melt gear pump is a melt gear pump for rubber and elastomer extrusion system. It is suitable for extrusion and conveying of rubber and elastomer melts; it is generally installed between the extruder outlet and the die head, and is used as a melt metering pump; the pump casing of the rubber extrusion melt gear pump has a built-in flow channel, which can be used as a melt metering pump. For cooling or heating with heat medium. However, due to the easy decomposition of rubber and other reasons, the conventional melt gear pump cannot meet its production needs due to its easy over-temperature. In addition, due to the pressure fluctuation of the upstream incoming material, which affects the size and quality of rubber products, there is usually a helical groove on the sleeve of the gear shaft that rotates in the same direction as the gear. To achieve the purpose of stabilizing the pressure of the melt pump, but a large amount of material flows out and causes waste. What are the advantages of Zhengzhou Bart's rubber extrusion melt gear pump?

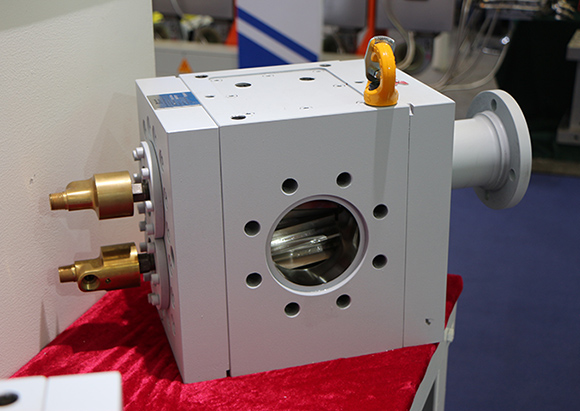

The rubber melt pump can prevent the melt gear pump from overheating, and can also stabilize the melt gear pump pressure without discharging a large amount of material. The rubber melt gear pump consists of a pump body, an end plate, a sealing sleeve, a pump body insulation cavity, a gear shaft, and a gear shaft sleeve. The gear shaft can be cooled. From the pump cavity to the outside, the three-way helical grooves are: co-rotating helical grooves with the gear shaft, vertical helical grooves with the gear shaft axial direction, and anti-rotating helical grooves with the gear shaft. These three helical grooves are connected and open at both ends. The center of the gear shaft is hollow, and a cooling circulation hole is opened on the gear shaft. Among the three-way helical grooves, the helical grooves close to the pump cavity that rotate with the gear shaft can discharge the materials to the outside, the helical grooves in the middle that are perpendicular to the axial direction of the gear shaft keep the materials and play a sealing role, and the helical grooves close to the outside rotate counter to the gear shaft. The spiral groove can push the material back into the pump cavity to prevent a large amount of material from being discharged. The hollow gear shaft with cooling circulation holes circulates through the cooling medium, so that the gear shaft is not easily overheated when meshing, so as to avoid the decomposition of the rubber. elastic extruder melt pump info@battemachinery.com