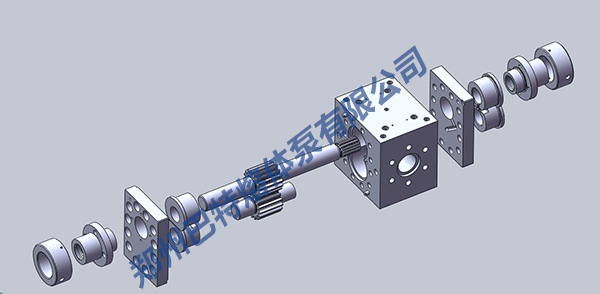

A complete extruder melt pump consists of motor, reducer, universal coupling and pump head. The pump head part is composed of a pump casing, front and rear side covers, gear shafts, sliding bearings and shaft seals. As a professional manufacturer of melt gear pump equipment for large and medium extruder manufacturers, Zhengzhou Batte not only provides well-manufactured products, but also provides comprehensive after-sales service guarantees to quickly respond to customer problems. This article specifically outlines the respective structures that make up the pump head.

The pump casing is generally integrally cast, and a pair of gear shafts and bearings that mesh externally are installed in the casing. , There are inlet and outlet flanges on both sides of the shell. The diameter of the inlet is larger than that of the outlet. This is particularly important for high-viscosity, low-pressure suction conditions, which can improve pump efficiency and operational stability. The front and rear side covers are actually flat end covers with jackets, coated with high-temperature sealant on the inner periphery, and are closely connected with the pump body through high-strength bolts to prevent melt leakage.

The extruder melt pump has a pair![]() of gear shafts, one long shaft and one short shaft. The long shaft is the driving shaft and the short shaft is the driven shaft. Gears include spur gears, helical gears, and herringbone gears. The tooth profile includes involute tooth profile and arc tooth profile. Involute spur gears are commonly used.

of gear shafts, one long shaft and one short shaft. The long shaft is the driving shaft and the short shaft is the driven shaft. Gears include spur gears, helical gears, and herringbone gears. The tooth profile includes involute tooth profile and arc tooth profile. Involute spur gears are commonly used.

There is an integral radial sliding bearing at both ends of the long shaft and the short shaft. The four bearings function as a bearing and as a baffle to block the side flow of the melt and the movement of the gear shaft. The lubrication of the bearing uses the delivered melt The body itself is lubricated. A longitudinal groove with a certain width and depth is opened on the inner diameter surface of the bearing near the pump outlet side. The melt pressure difference between the outlet and the inlet is used to guide the melt into the journal gap and pass through the pump housing and side cover. The upper lubrication channel returns to the low pressure side of the inlet to achieve the purpose of lubrication.

Zhengzhou batte melt pump is a professional manufacturer of melt pumps for extruders. With many years of experience in melt pump R&D and production, it provides melt delivery, pressurization and metering equipment for thousands of domestic and foreign enterprise users. Welcome to consult and purchase. info@battemachinery.com.