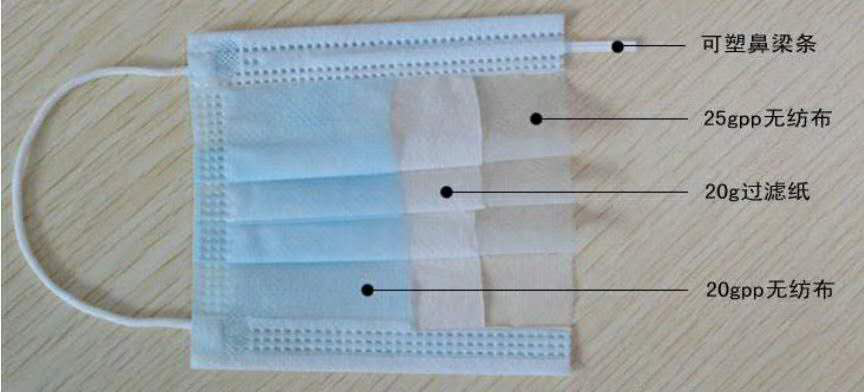

Since the outbreak of new coronavirus pneumonia, the supply of masks and other medical protective articles in various parts of the country has been in short supply. From the point of view of mask composition, medical surgical masks generally have three layers: the inner and outer two layers are non-woven fabric, and the middle filter layer is melt blown fabric. "Melt blown cloth" is commonly known as the "heart" of the mask. It has good filtration, shielding, heat insulation and oil absorption. It is an important raw material for the production of medical surgical masks and N95 masks.

The main material of melt blown cloth is polypropylene, which is a kind of superfine electrostatic fiber cloth with the diameter of about 2 microns. Its diameter is only one tenth of the diameter of the outer fiber of the mask, which can effectively capture dust. When the droplets containing virus are close to the fusible spray cloth, they will also be adsorbed on the surface by static electricity and cannot be penetrated. Therefore, it is a necessary raw material for the production of filter masks.

Melt blown cloth is a kind of non-woven fabric. Nonwovens, also known as nonwovens, are made of oriented or random fibers, without warp and weft threads. They are named for their appearance and some properties similar to textile fabrics. At present, there are many processing technologies for non-woven fabrics, such as spunbond, melt blown, hot rolling, spunlace and so on. Among them, the melt blown non-woven fabric is called melt blown non-woven fabric. Melt blown method refers to the spinning method that makes the polymer melt just extruded stretch and solidify rapidly by means of high-speed hot air flow.

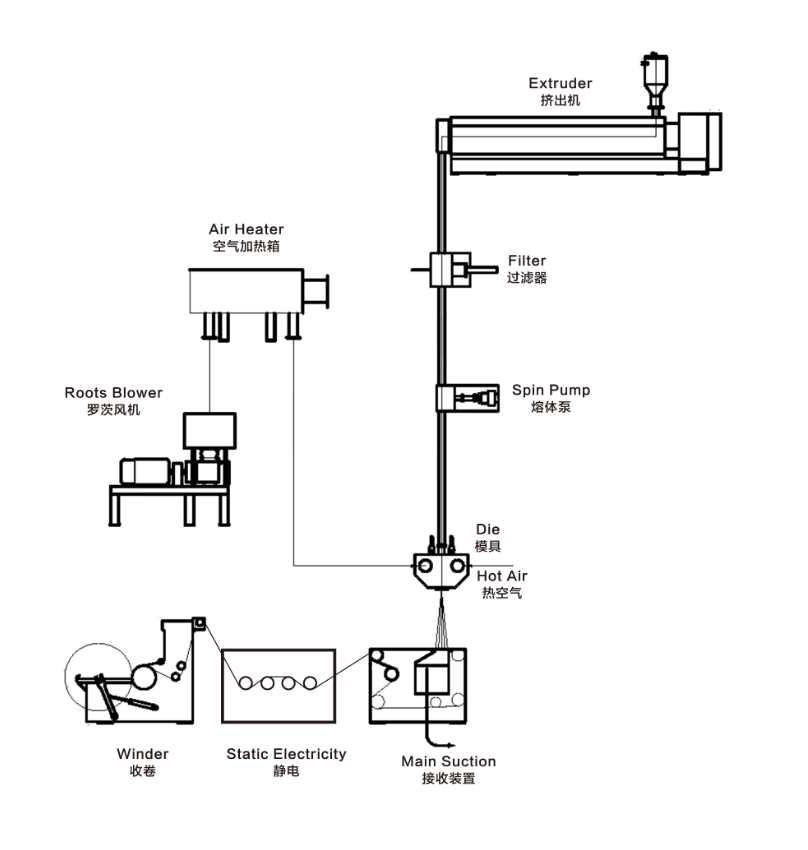

The non-woven fibers produced by melt blown process are finer, with larger surface area, better filtration, shielding, heat insulation and oil absorption, which are incomparable to those produced by other processes. The following figure is the principle diagram of melt blown cloth production by melt blown process.

Melt blown cloth is produced by melt blown process. The equipment mainly includes: screw extruder, melt pump, mesh changer, melt blown device, winding device, air system (hot air blower and heater), etc. The function of the screw extruder is to melt the slice material; the function of the melt pump is to precisely measure, control the output and the fineness of the fiber, and continuously and evenly transport the melt to the spinneret. The function of the screen changer is to filter out the impurities in the melt so as not to block the spinneret hole. The function of the winding device machine is to wrap the melt blown cloth into rolls. The function of the air system (hot air blower and heater) is to provide the temperature and pressure of the hot air used for spinning air stretching.

The model and configuration of melt metering pump and filter in the melt blown cloth production line are as follows:

| Standard configuration of metering pump and filter (screen changer) in melt blown cloth production line | ||||

| Screw specifications | Output |

Width of melt blown cloth | Model of metering pump |

Model of filter (screen changer) |

| Φ45 | 10-20kg/h | 600mm | ZB-M-10CC | ZB-2MR-100 |

| Φ65 | 20-60kg/h | 1200mm | ZB-M-20CC | ZB-2MR-120 |

| Φ90 | 60-100kg/h | 1600mm | ZB-M-30CC | ZB-2MR-150 |

| Φ105 | 80-150kg/h | 2400mm | ZB-M-50CC | ZB-2MR-175 |

| Φ120 | 150-200kg/h | 3200mm | ZB-M-100CC | ZB-2MR-195 |

Filter level of mask

N95 is one of nine dust masks certified by NIOSH (American Institute of occupational safety and health). N represents that its material is only suitable for filtering non oily dust, and 95 represents that its filtering efficiency reaches at least 95%.

N. What do R and P mean?

According to NIOSH's classification definition of filter materials,

N series: protection of non oil suspended particles, no time limit;

R Series: protect non oil suspension particles and sweat oil suspension particles for eight hours;

P Series: protect non oil suspension particles and sweat oil suspension particles without time limit;

Is N95 a good mask?

NIOSH divides the standards of respirators into three categories: N-series, R-Series and P-Series. N is non oil particles, R and P are oil particles, but R-class can only protect oil particles for eight hours, while p-class has no such limitation. These three categories have three standards of filtering efficiency: 95 (95%), 99 (99%) and 100 (99.97%), so there are nine kinds of respirators in total. Because biological particles are mostly non oil particles, n-grade can be used. N95 indicates that the filtration efficiency of non oil particles is 95%, and N95 is a very basic level among all certification levels.

In December 2019, due to the impact of China's domestic epidemic situation, there was a huge gap in the demand for masks, especially for masks with medical protection level, the filtering accuracy reached 99%, which made it difficult to find the corresponding qualified melt blown cloth. If there is no melt pump and filter installed in the melt blown cloth production line, the quality of the melt blown cloth products can not meet the inspection requirements. Recently, many extruder manufacturers have turned to manufacturing melt blown cloth production line, which leads to the market confusion. When we go to the production line, we must polish our eyes, compare more and choose more.