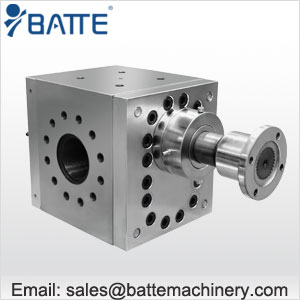

The main function of batte melt pump for conveying plastic melt is to pressurize and stabilize the high temperature plastic melt from the extruder and keep the melt flow accurately and steadily into the extruder head. It can be high temperature 350 ℃, pressure up to 35MPA or higher under the conditions of continuous work. Its main features are simple and compact structure, reliable work, longer life expectancy.

Batte melt pump is a pump body, front and rear cover, two intermeshing gears, bearings and seals and other components. The space formed by the two-toothed toothed gallery, the pump body and the side cover forms the pump's feed, delivery and discharge area. Gear is the core part of the melt pump, and its structure varied: According to the meshing mode can be divided into internal and external meshing; according to the curve of the tooth gallery can be divided into involute gear, circular arc gear, cycloid gear; According to the tooth can be divided into spur gears, helical gears and herringbone teeth, but the most common in the transport of plastic melt involute spur or helical gear pump.