The flow rate of the melt pump head varies with the change of the outlet pressure, but the fluctuation of the general outlet pressure can not exceed (+10 psi). If the fluctuation is large, it is likely to be a transmission problem, and the transmission parameters need to be adjusted.

The combination of melt pump and extruder can transport melt materials more stably, provide extrusion pressure more effectively and improve melt quality. The melt pump can eliminate many variables affecting the output stability of extruder by controlling the melt output.

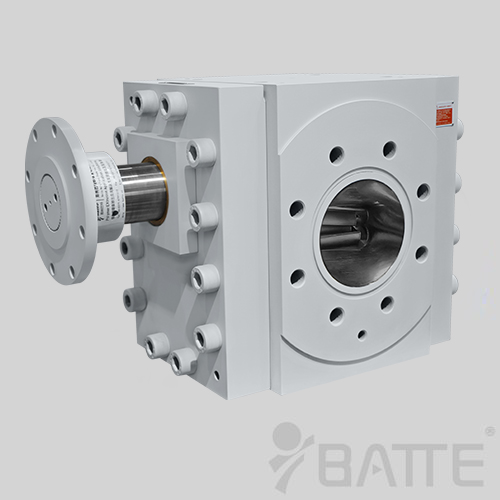

The bearings of melt pumps are lubricated by melt. In order to adapt to different melt viscosity and pump pressure, water-cooled seals are installed in most pumps. After starting the melt pump, it is reasonable that the temperature of the melt pump is below 3-6 degrees Celsius. If the temperature of the melt pump is much higher than the set temperature or the actual melt temperature, it means that the mechanical part of the pump or the temperature control instrument is out of order.