The service life of a plastic bottle cap melt pump does not have a fixed number of years, as it is influenced by various factors, including the pump body material, operating environment, maintenance condition, workload, operating mode, and lubrication conditions. Below is a detailed analysis of these factors and how they affect the service life of the melt pump:

Pump Body Material:

The choice of material has a significant impact on the life of the melt pump. Materials that are corrosion-resistant and high-temperature-resistant, such as stainless steel and alloy steel, can enhance the durability of the pump body.

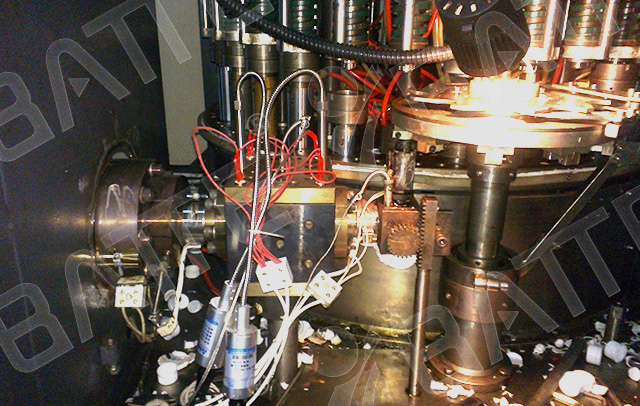

Operating Environment:

The melt pump operates in environments with high temperatures, high pressures, and high viscosities. Therefore, the cleanliness of the operating environment and suitable temperature and pressure conditions have an important impact on the life of the pump body. Maintaining a clean and suitable operating environment helps extend the service life of the melt pump.

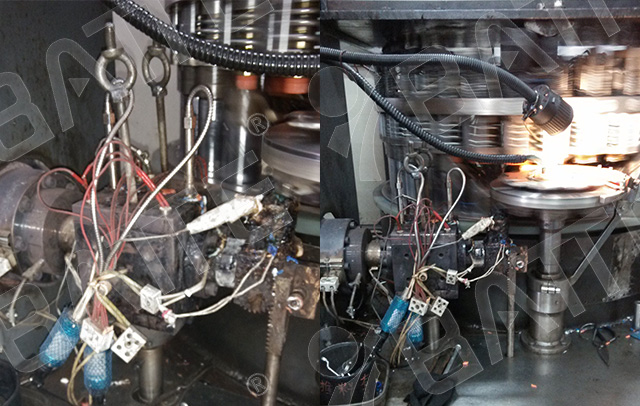

Maintenance:

Regular maintenance of the melt pump, such as cleaning, lubrication, and inspection, can promptly identify and resolve issues, preventing faults from occurring, and thereby extending the service life of the pump body.

Workload:

The workload of the melt pump also affects its life. Under prolonged high-load operation, the wear on the pump body intensifies, shortening its life. Therefore, using the melt pump under a reasonable workload can extend its service life.

Operating Mode:

Correct operating practices are also crucial for extending the life of the melt pump. Following operating procedures and avoiding excessive acceleration, deceleration, or sudden shutdowns can reduce wear and faults on the pump body.

Lubrication Conditions:

The friction index of the melt pump increases during prolonged high-speed operation. The use of lubricant oil can reduce friction, prevent wear on components, and avoid other faults caused by heat generation in the melt pump, thereby extending its service life.

Taking into account the above factors, although it is not possible to provide a specific number of years for the service life of a plastic bottle cap melt pump, generally speaking, through reasonable material selection, operating environment control, maintenance, workload management, correct operating practices, and good lubrication conditions, the service life of the melt pump can be significantly extended. In practical applications, it is recommended to conduct regular inspections and maintenance based on specific circumstances to ensure the stable operation of the melt pump and extend its service life.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071