Melt pump is a kind of equipment used to convey high temperature and high viscosity plastic melt, which is mainly used in plastic extrusion, injection molding, blow molding and other production processes. The speed range of melt pump refers to the range in which the speed of the pump can be adjusted.

sheet extrusion melt pump

In the selection of melt pumps, the following aspects need to be taken into account:

1, melt viscosity: the higher the melt viscosity, the lower the required pump speed.

2, the production process: different production processes have different requirements for melt pumps. For example, in injection molding production, a higher flow rate and lower pressure is required; while in extrusion production, a higher pressure and lower flow rate is required.

3, raw material characteristics: different kinds of raw materials on the melt pump also has different requirements. For example, for raw materials containing particles or fiber impurities, the need to use wear-resistant pump head and rotor.

4, the melt pump model: different models of melt pumps have different speed range and flow range, you need to choose the right model according to production requirements.

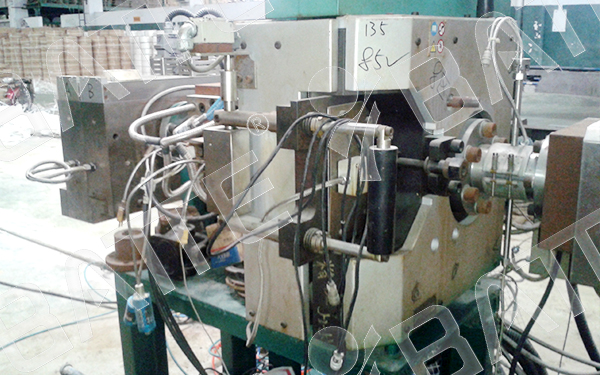

high temperature melt gear pump

Melt pump speed range is generally between 30 ~ 120rpm, the specific speed range depends on different models of melt pumps and different production process requirements. In practice, according to the production process and raw material characteristics to choose the right type of melt pump and speed.

melt pump for plastic extrusion

In short, the melt pump speed range is based on the production process and raw material characteristics to decide, choose the right melt pump and adjust the appropriate speed can improve production efficiency and product quality.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071