To ensure product quality, one or more sets of melt pumps and filters are generally used in the production line of cast film and laminated film. Studying their performance characteristics, analyzing the causes of defects and choosing the right melt pumps and filters can significantly improve the production efficiency and yield of cast film and create greater economic benefits. The production of bi-directional cast film and paper lamination requires high sealing of screen changer and high production temperature, so the common screen changer basically has the problem of material leakage or seepage, Batte plate cast film and lamination special screen changer's special sealing structure design, under the high temperature of 340 ℃, the screen changer normal production, no material leakage, no seepage.

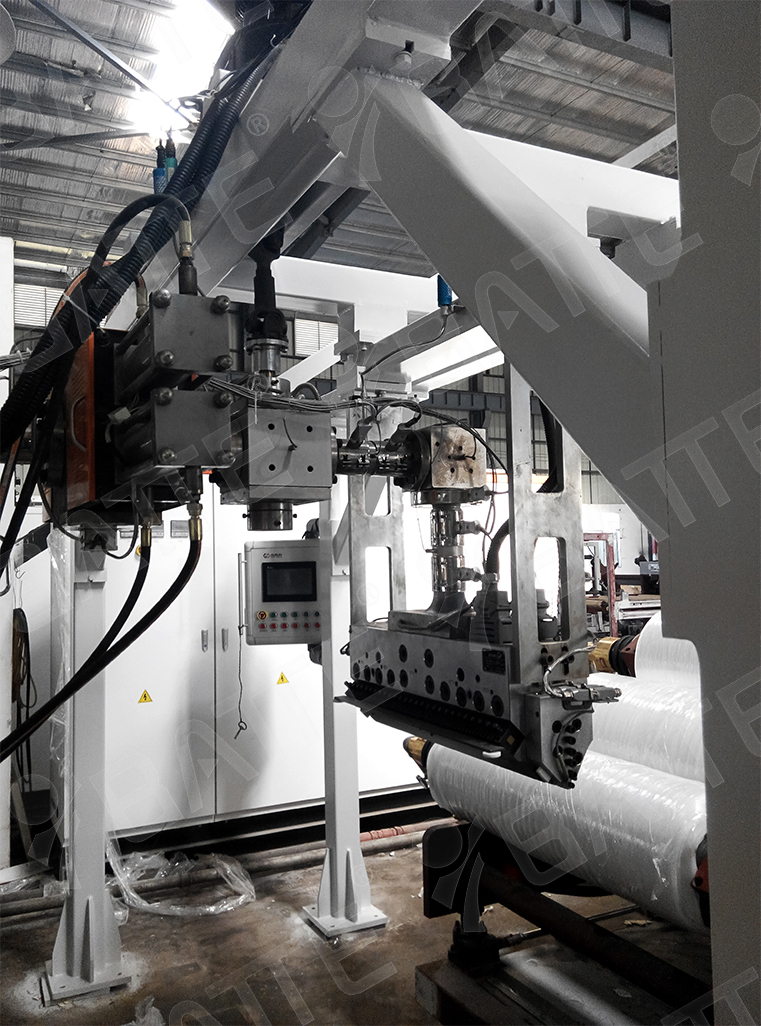

Cast film installation plan

The advantage of using single plate and single station is that it avoids the long time heat preservation and heating of the spare filter station outside the main body of the screen changer and the aging of the raw material in the screen plate, and there is a certain temperature difference between the temperature and the production temperature, which will affect the production after the screen change. If you want to achieve the requirement of continuous production without stopping, you can use Batte mesh belt type automatic screen changer (pressure 35MPA), no manual operation, fully automatic production, continuous production without influence, no material leakage, which is a very good choice and a more cost-effective choice.

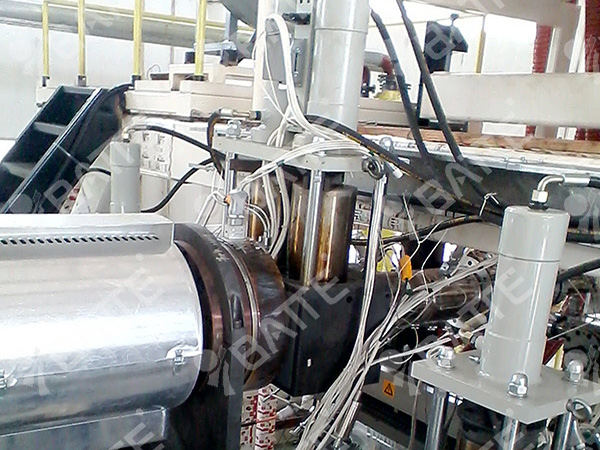

Laminated film installation solutions

Because of its process characteristics, the production of laminated film is generally higher than other industries in the production process temperature, reaching more than 300 degrees, up to 340 degrees, the fluidity of the melt is strong, so there are very high requirements for the sealing of the screen changer, otherwise it will leak after the material, Batte single-plate single-station screen changer with a special structure design, to ensure that under high temperature (340 ℃) conditions, no leakage, easy and fast screen change It makes the production more smoothly.

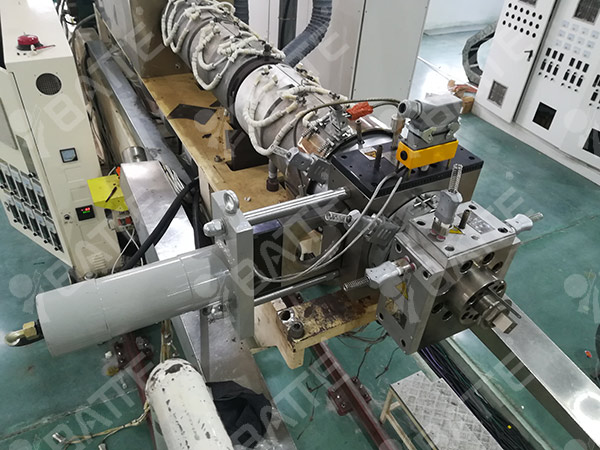

The melt pump adopts the overall hardening technology and is made of high, corrosion-resistant high-temperature alloy steel M2 material. On the basis of the standard series melt pump, the design parameters of the pump body are strengthened, such as the requirements of high torque and low shear, as well as the requirements of high corrosion resistance (fluorine containing products). The self-lubrication system of the pump body, the import and export flow channels and the gear structure have been optimized. It is suitable for the extrusion of PC, PMMA, PVC and other products with high gloss and high transparency requirements as well as heat-sensitive materials.

The melt pump adopts the overall hardening technology and is made of high, corrosion-resistant high-temperature alloy steel M2 material. On the basis of the standard series melt pump, the design parameters of the pump body are strengthened, such as the requirements of high torque and low shear, as well as the requirements of high corrosion resistance (fluorine containing products). The self-lubrication system of the pump body, the import and export flow channels and the gear structure have been optimized. It is suitable for the extrusion of PC, PMMA, PVC and other products with high gloss and high transparency requirements as well as heat-sensitive materials.